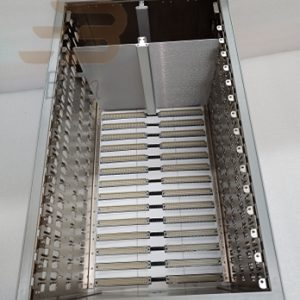

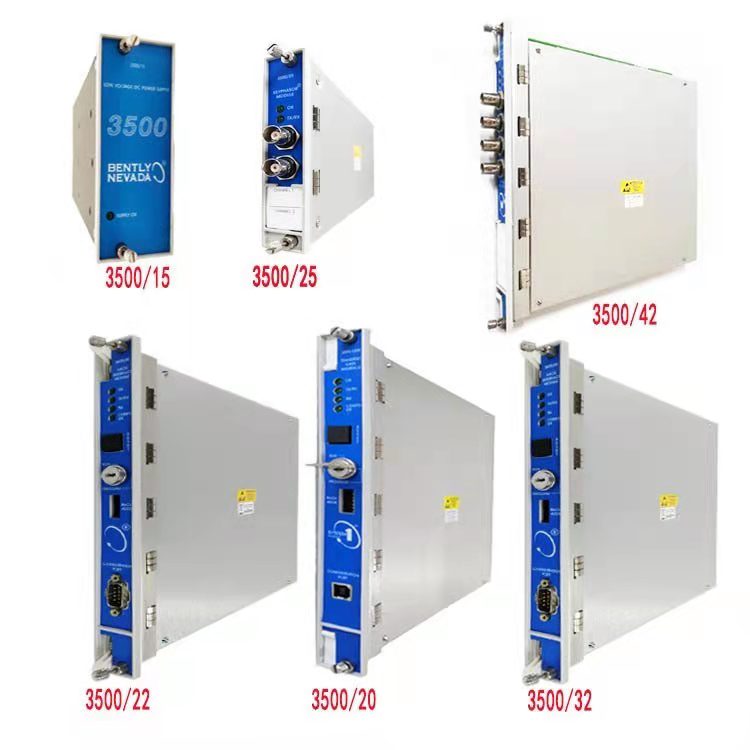

The Bentley 3500 system is used for vibration monitoring and protection of large machinery. The Bentley 3500 system must be equipped with frame 3500/05, power supply 3500/15, frame interface module 3500/22M, etc.

The online vibration monitoring system for wind turbines mainly consists of vibration data acquisition, communication, monitoring, analysis and remote control, the specific system architecture is shown in Figure 1. Vibration sensors detect the vibration of the wind turbine drive chain and convert the vibration signal into an electrical signal at the front-end processing layer. The data acquisition cabinet in the nacelle conditions the electrical signals detected by the sensors and converts them into digital signals by A/D. The converted digital signals are sent to the back-end processing layer via the wind farm fibre optic ring network.

At the same time, the digital signals transmitted to the central control room can be sent to the remote monitoring centre through the interconnection network to achieve remote analysis and diagnosis of wind turbine vibration data. The online vibration monitoring of wind turbines, the data acquisition station, the intranet server and the wind turbine vibration analysis software are all located within the wind farm LAN and operate independently of the external network. The wind turbine vibration information from the wind farm LAN can be sent to the remote monitoring centre via Ethernet via the on-site network isolator.

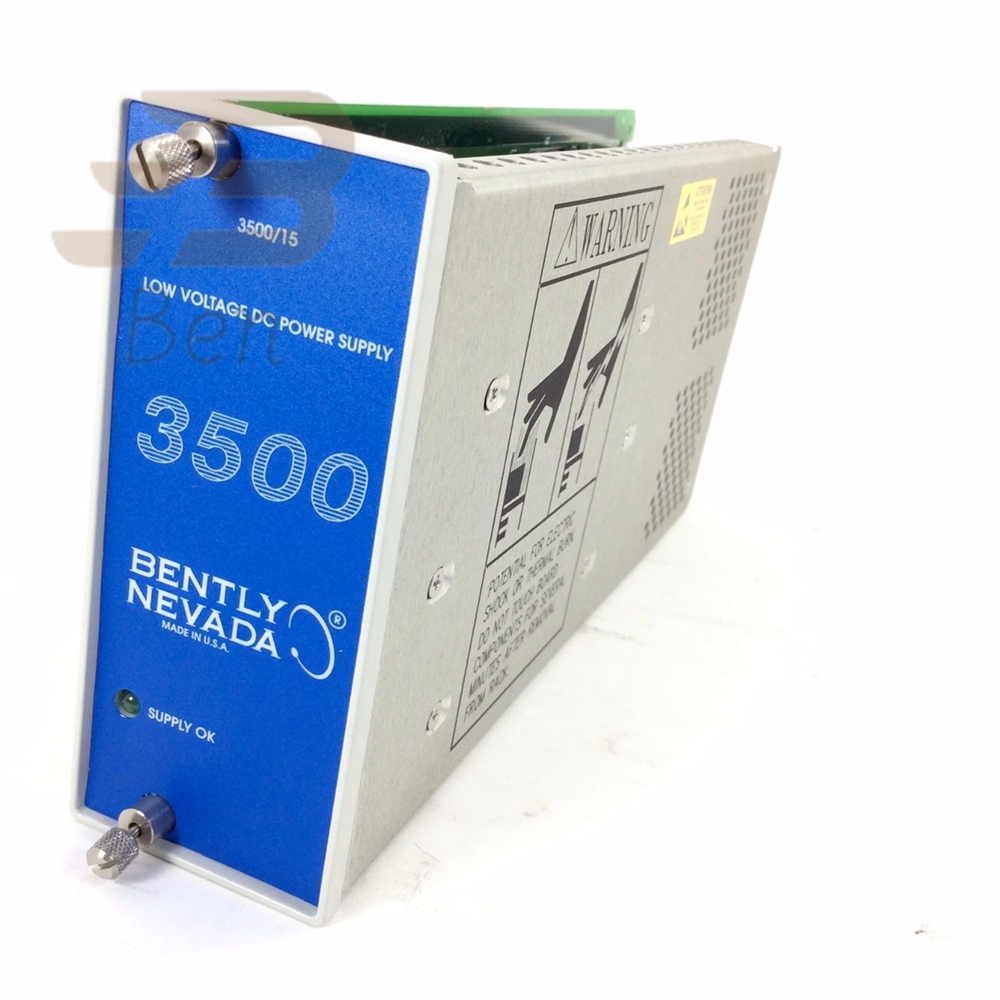

bently3500 Bentley power supply high voltage 220V AC, spare parts as follows

127610-01 AC power supply module

125840-01 High Voltage AC Power Input Module (PIM)

125840-02 Low voltage AC power input module (PIM)

129486-01 High voltage DC power supply module

129478-01 High Voltage DC Power Input Module (PIM)

133292-01 Low Voltage DC Power Supply Module

133300-01 Low Voltage DC Power Input Module (PIM)

01720025 Spare fuses (two types of AC PIM and high voltage DC PIM)

01720045 Spare fuse (low voltage DC PIM)

The hardware of the online vibration monitoring system generally consists of four parts: sensors, signal conditioning, data acquisition stations and servers. The sensors mainly include displacement sensors and speed sensors. Signal conditioning isolates, amplifies, compensates and transforms the weak signals collected, with strong long-distance driving capability and anti-interference capability. The data acquisition station converts the collected analogue quantities into digital quantities to facilitate system analysis and processing. The vibration data acquisition system completes the sampling, signal conditioning and data output of the vibration data.

The order information and type description of the Bentley power supply bently 3500/15 are as follows.

3500/15-AXX-BXX-CXX Description of options

A: Power supply type (upper slot)

01 Low voltage AC (85-132 Vac rms)

02 High voltage AC (175-264 Vac rms)

03 High voltage DC (88-140 Vdc)

04 Low voltage DC (20-30 Vdc)

05 Universal AC power supply (85-264 Vac rms)

B: Power supply type (lower slot)

00 No power supply (only for use where a single power supply is required)

01 Low voltage AC (85-132 Vac rms)

02 High voltage AC (175-264 Vac rms)

03 High voltage DC (88-140 Vdc)

04 Low voltage DC (20-30 Vdc)

05 Universal AC power supply (85-264 Vac rms)

01 CSA/NRTL/C

02 ATEX/IECEx/CSA (Class 1, Zone 2)

CN China

The specific models are as follows

3500/15 (front panel 127610-01, rear back panel 125840-01)

3500/15-02-02-00, upper slot & lower slot both fitted, so dual power supply

3500/15-02-00-00, upper slot fitted, lower slot not fitted, so single power supply

3500/15-05-05-00, both upper and lower slots, so dual power supply

The following are the upgraded 3500/15 universal AC power modules.

3500/15 (front panel 106M1079-01, rear back panel 106M1081-01)

3500/15-05-05-00, both upper slots & lower slots fitted, so a dual power supply set

3500/15-05-00-00, upper slot fitted, lower slot not fitted, so single power supply set

Bently Nevada product structure diagram:

I. Monitoring System

1. Continuous online monitoring system

A.3500 Series

B.3300 Series

C.1900 Series

D.ADAPT Wind Wind turbine online monitoring

2. Patrol online monitoring system

A. Inspection and monitoring

B.Essential Insight.Mesh wireless solution

C.AnomAlert motor anomaly detection

II.Sensor

1.Eddy current sensor

2.Velocity acceleration sensor

3. Pressure sensors

4. Housing expansion and valve position sensors

5. Optical sensors

Portable diagnostic instruments

1. Portable diagnostic equipment ADRE system: ADRE 408 DSPi hardware

Peal. Portable data acquisition and analyser: SCOUT100/140

IV. Test and calibration equipment

Eddy current probe calibrator:TK-3 condition monitoring calibrator

Other test and calibration equipment: Testers for TIM testing using Snapshot

High accuracy micrometer

Rotor test benches

Velomitor power supply module keyed to signal multiplier/divider torsional vibration signal conditioner oscilloscope excuse module

The sensor measurement method uses acceleration measurement and the output is achieved through the vibration monitoring module to obtain acceleration measurements in the X, Y and Z directions. The system uses MEMS (Micro Electro Mechanical Systems) accelerometers, which have developed rapidly in recent years, as vibration detection sensors. These sensors are characterised by low cost, low power consumption, wide measurement range and good dynamic performance. The external interface is simple and convenient to use and can fully meet the vibration detection needs of wind turbines.

The sensor installation configuration is: the main shaft is to be configured with three vibration acceleration sensors, the gearbox is to be configured with five vibration acceleration sensors, the generator is to be configured with three vibration acceleration sensors, and another speed sensor is to be configured to collect the high-speed shaft speed.

The signal acquisition mainly consists of signal conditioning (including signal converter, signal pre-processing) and data acquisition module, which completes the collection of vibration signals from each measurement point of the wind turbine, ensures that the signals are not distorted and attenuated when they are transmitted from the wind turbine to the control room, and converts the analogue electrical signals into digital signals through A/D and sends them to the upper computer to realise the display and analysis functions of the upper computer on the digital signals. The acquisition station also has the functions of parameter setting, data acquisition, data storage, communication and early warning. The signal conditioning part of the data acquisition system is usually embedded in the acquisition card in the acquisition station, which can both complete the signal conditioning and realise the signal A/D conversion function.

We do other brands: ABB, Allen-Bradley, Schneider, GE (General electric), Westinghouse, FANUC, Bently, KUKA, Foxboro, Triconex, Honeywell, YASKAWA, etc., if you need, you can contact me, look forward to your consultation.