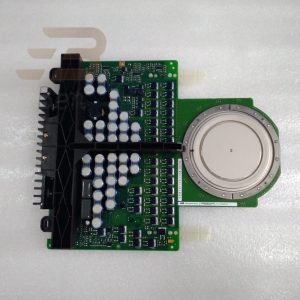

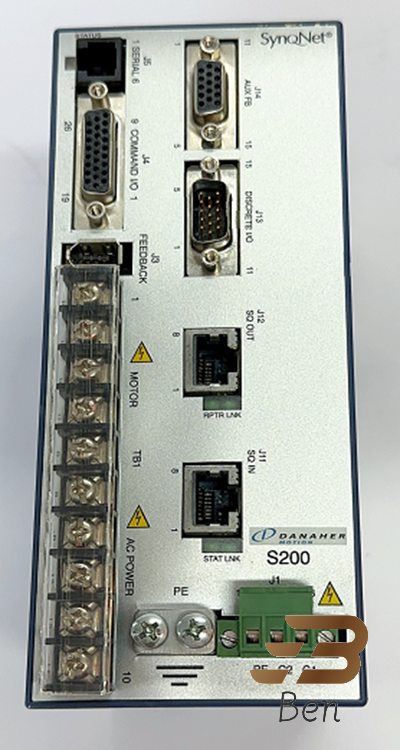

SC902-001-01 Brushless Servo Drive Kollmorgen / Pacific Scientific

SC902-001-01 Brushless Servo Drive Kollmorgen / Pacific Scientific

SC902-001-01 Brushless Servo Drive Kollmorgen / Pacific Scientific

Servo drives (servo drives), also known as “servo controller”, “servo amplifier”, is used to control servo motors, a controller, its role is similar to the role of the inverter in the ordinary AC motor, belongs to a part of the servo system! It is mainly used in positioning system. Generally through the position, speed and torque three ways to control the servo motor, realize the positioning of the drive system, is the product of transmission technology.

6410-001-C-H-N

6410-001-N-N-K

6410-009-N-N-N

6410-024-N-N-N

PC833-001-N-BA

PC834-101-N

PC842-001-T

PC844-XYZ-N

SC322A-001-01

SC903TN-001-01

SC953TN-501-01

Mainstream servo drives are using digital signal processor (DSP) as the control core, which can achieve more complex control algorithms, digital, networked and intelligent. Power devices are generally used to intelligent power module (IPM) as the core design of the drive circuit, IPM internal integrated drive circuit, at the same time with over-voltage, over-current, overheating, under-voltage and other fault detection and protection circuits, in the main circuit is also added to the soft-start circuit to reduce the start-up process on the impact of the drive. The power driver unit first rectifies the input three-phase power or utility power through a three-phase full-bridge rectifier circuit to obtain the corresponding DC power. After the rectified three-phase power or utility power, then through the three-phase sinusoidal PWM voltage inverter frequency to drive three-phase permanent magnet synchronous AC servo motor. The whole process of the power drive unit can be simply said to be the process of AC-DC-AC. The main topology circuit of the rectifier unit (AC-DC) is a three-phase full-bridge uncontrolled rectifier circuit.

Single power input

Input voltage from 24 to 75 VDC for a variety of power supplies

Output current adjustable via 3-position DIP switches with RMS values ranging from 0.625 to 5 amps

4-phase bipolar chopper drive for current regulation and low ripple current

DIP switch selectable microstep resolution up to 51,200 steps per revolution

Lower idle current reduces motor heat in many applications

Optional stepper filter eliminates noise on stepper inputs

Fault protection:

Line-to-line and line-to-neutral shorts

Internal power supply undervoltage

Bus overvoltage

Compact design

Servo drive is an important part of modern motion control, which is commonly used in industrial robots and CNC machining centers and other automation equipment. In particular, servo drives applied to control AC permanent magnet synchronous motors have become a hot research topic at home and abroad. The current AC servo drive design is generally based on vector control current, speed, position 3 closed-loop control algorithm. The algorithm in the speed closed-loop design is reasonable or not, for the entire servo control system, especially the speed control performance plays a key role.

If you need to inquire or purchase ,please send the product models to my email or call me directly .

Contact detail:Mobile/ WeChat/ WhatsApp:+86-15396237607

E-mail:2322181769@qq.com

QQ: 2322181769

Control Systems (DCS, PLC/SPS, CNC): Panel Controllers, HMI and Display Panels, Industrial PCs, Drives (Inverters and Servo Systems), Motors, Power Supplies

Allen-Bradley:ControlLogix 1756 series controller, CompactLogix 1769 series controller, SLC 500 1747 1746 series controller, PLC-5 1771 1785 series controller, ProSoft:mvi 69/PS69/mvi 56/mvi 94/mvi 71/ mvi 46/3150, ICS TRIPLEX Trusted System

ABB:AC800M Series Controller I/O Modules, AC800F Series Controller Modules, AC31 Series Controller Modules, 800xA Series Modules, Bailey INFI 90 Modules, DSQC Robot Module Spare Parts, Advant OCS System Spare Parts, H&B Freelance

Bentley Nevada: Bently 3500 monitoring system, Bently 3300 monitoring system, preamplifier, eddy current sensor probe

Schneider:Quantum 140 series:Modicon M340, Modicon Premium :CPU processor module, communication module, etc.

Emerson:Ovation system DCS card, DeltaV system dual-channel redundant safety system, redundant controller

General Electric: IS200/DS200 series excitation system card, IC 693/IC 695/IC 697/IC 698/IC 200/IC 660/IC 670 CPU module, communication module, analog-digital module

Invensys Triconex Cards:Tricon System Cards

Invensys Foxboro:I/A Series System Modules

Honeywell:Alcont, Experion LS, Experion PKS, Experion HS, Plant Scape, TDC 2000, TDC3000, TPS

Yokogawa:CS3000 System CPUs