Servo motor

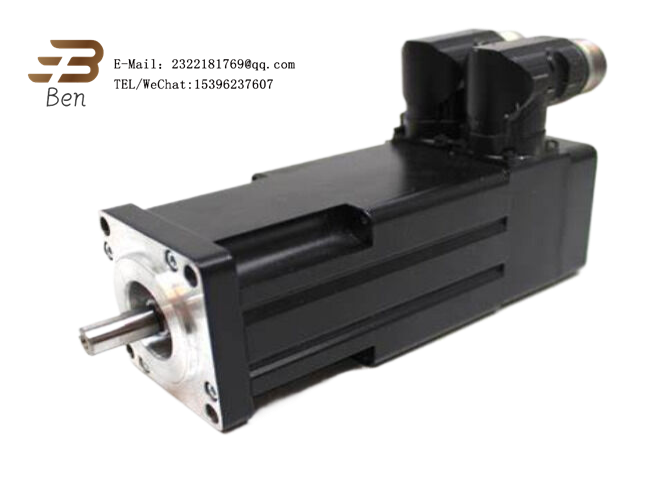

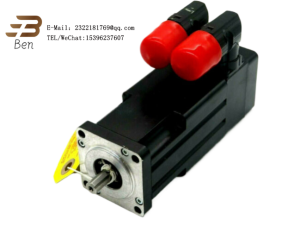

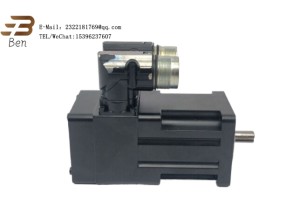

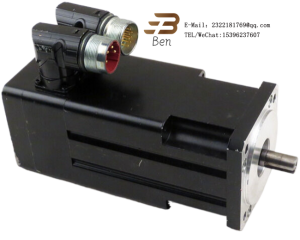

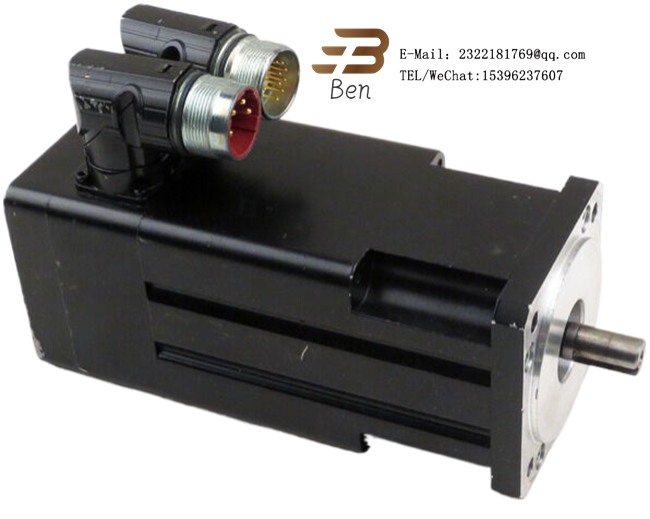

MPLS-A210E-VJ42AA Servo motor Rockwell Automation

MPLS-A210E-VJ42AA Servo motor Rockwell Automation

Servo Motor, Rotary, Low Inertia, IEC, 230V AC, 2750 rpm Base, 1 Stack Length, Right Angle Rotatable DIN Connector, Multi-Turn High Resolution Encoder Feedback, 75 mm Bolt Circle Metric Flange Mounting, Keyed Shaft.Rockwell Automation announces that as of November 30, 2011, the Servo Motor, Rotary, Low Inertia, IEC, 230V AC, 2750 rpm Base, 1 Stack Length, Right Angle Rotatable DIN Connector, Multi-Turn High Resolution Encoder Feedback, 75 mm Bolt Circle Metric Flange Mounting, Keyed Shaft will be discontinued and no longer available for sale.

The Rockwell servo motor, also known as the AB Rockwell servo motor, is a commonly used industrial control device with a complex structure and multiple components. In the field of industrial automation, servo motors play a vital role in the precise control of mechanical motion, making the production process more efficient and accurate.

Rockwell servo motor is mainly composed of several main parts, such as the motor itself, the sensor, the controller and the power supply. Among them, the motor itself is the core part of the servo motor, which is composed of the rotor and the stator, etc., and can achieve high-precision motion control. The sensor is used to detect the motion state of the motor, such as position, speed and acceleration, etc., to provide feedback signals for the controller, so as to achieve closed-loop control. The controller is the brain of the servo motor, which is responsible for receiving the command signal, calculating the control amount according to the feedback signal, and controlling the movement of the motor. The power supply provides a stable power supply to the servo motor.

Rockwell servo motors have many advantages, such as high precision, fast response, good stability and high reliability. At the same time, it also has a wide range of applications, can be used in a variety of mechanical equipment, such as CNC machine tools, printing machinery, packaging machinery, textile machinery and so on. In addition, Rockwell servo motors can be seamlessly connected to various industrial automation systems for remote monitoring and control.

It should be noted that Rockwell servo motor is a high-precision and high-performance industrial control equipment, so it needs to be selected and configured according to actual needs and application scenarios when selecting and using. In addition, during use, regular maintenance and maintenance are also required to ensure its long-term stable operation.