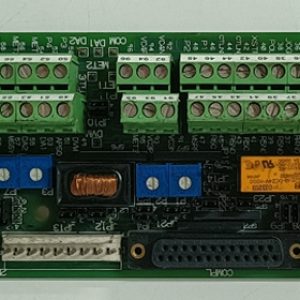

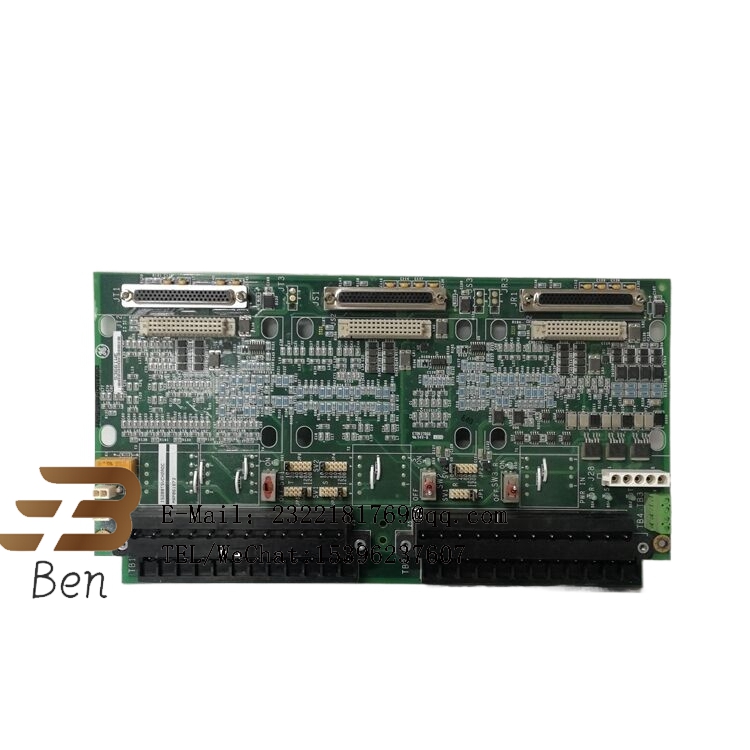

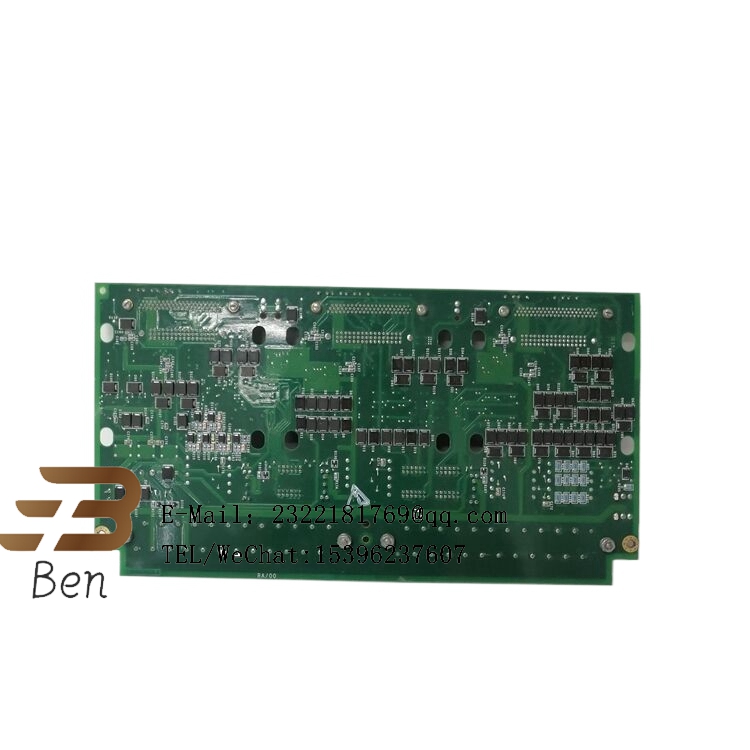

IS200EGPAG1BCA Control module

The IS200EGPAG1BCA is a powerful intelligent motor starter control module with several key functions for industrial automation and control systems.

IS200EGPAG1BCA also has some other features. For example, it supports multiple input types (such as normally open/normally closed contacts) and has a compact design for easy installation and deployment. At the same time, the module also has a wide operating temperature range, which can be adapted to various working environments.

IS200EGPAG1BCA product features Main description:

Motor control: The IS200EGPAG1BCA allows users to start and stop motors remotely or locally to meet the needs of the production process. This provides users with a flexible mode of operation, making the control of the motor more convenient.

Protection mechanism: The module has overload protection, which monitors the motor current and prevents damage due to overload through built-in thermal overload relay or electronic overload protection. In addition, it also has a short circuit protection function, in the event of a short circuit can quickly cut off the power, protecting the motor and circuit from damage. At the same time, the IS200EGPAG1BCA also monitors the power supply voltage to ensure that the motor is operating within a safe voltage range, providing undervoltage and overvoltage protection.

Reversible control: IS200EGPAG1BCA supports reversible operation of the motor, that is, positive and negative rotation control. This allows the motor to be flexibly adjusted according to the specific application requirements.

Remote monitoring and communication: Through the communication interface and protocol, IS200EGPAG1BCA can be connected with the upper computer system or industrial automation network to achieve remote monitoring and control. This provides users with real-time motor status information and convenient control methods.

Data reading and processing: As an intelligent module, IS200EGPAG1BCA can read PLC data and intelligent instruments (such as flow meters, analyzers and other equipment) data. This allows it to play a key role in industrial automation systems, providing accurate data support.

.png)