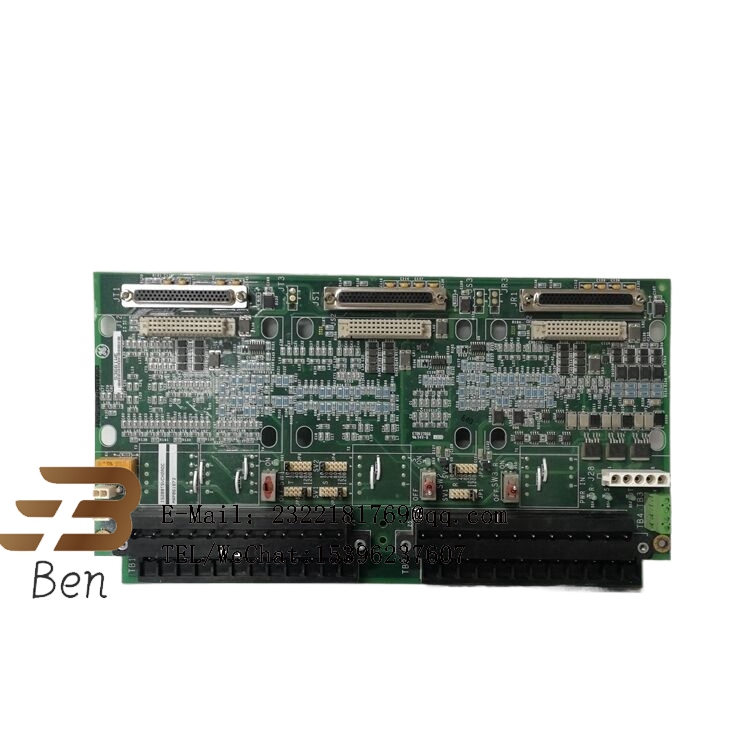

IS200TRLYS1BGG Separate I/O board

The IS200TRLYS1BGG is a separate I/O board designed for use in steam turbines and other industrial equipment. The board is a board component of the GE Mark VI system, which is used to manage and control industrial gas and steam turbines. As one of the MKVI’s many discrete I/O boards, the IS200TRLYS1BGG has several important functions.

First, it is able to receive signals from steam turbines and other equipment and convert them into a format that can be recognized by the control system. These input signals may include parameters such as temperature, pressure, and liquid level, which are used to monitor the operating status of the steam turbine. Secondly, according to the processing results of these input signals, the board can output control signals to control the operation of the steam turbine. For example, when the temperature of a steam turbine exceeds a set point, the IS200TRLYS1BGG may output a signal to reduce the power of the steam turbine or start the cooling system.

In addition to the basic input/output functions, the IS200TRLYS1BGG also has fault diagnosis and protection functions. It can detect and deal with abnormal situations, such as equipment failure or abnormal operation, in a timely manner to ensure the safe and stable operation of the steam turbine. This is essential for maintaining the continuity and stability of industrial processes.

In addition, the IS200TRLYS1BGG has other specific features. For example, it can adjust the cutting length by pressing a key or a finger switch, and is especially suitable for flying saws and flying shears, providing maximum cutting performance and accuracy. At the same time, its short position control period and intelligent arithmetic ensure the highest cutting accuracy.

.png)

Reviews

There are no reviews yet.