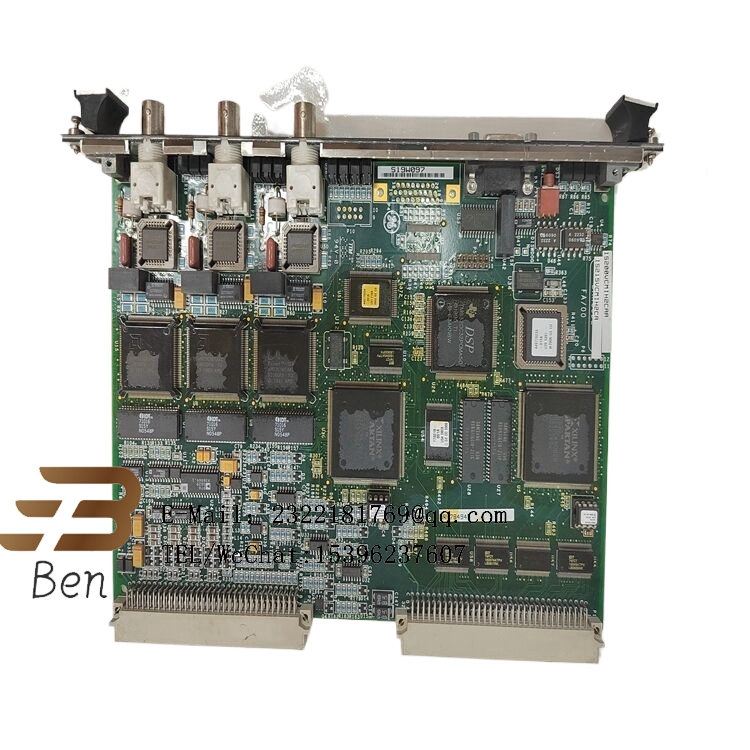

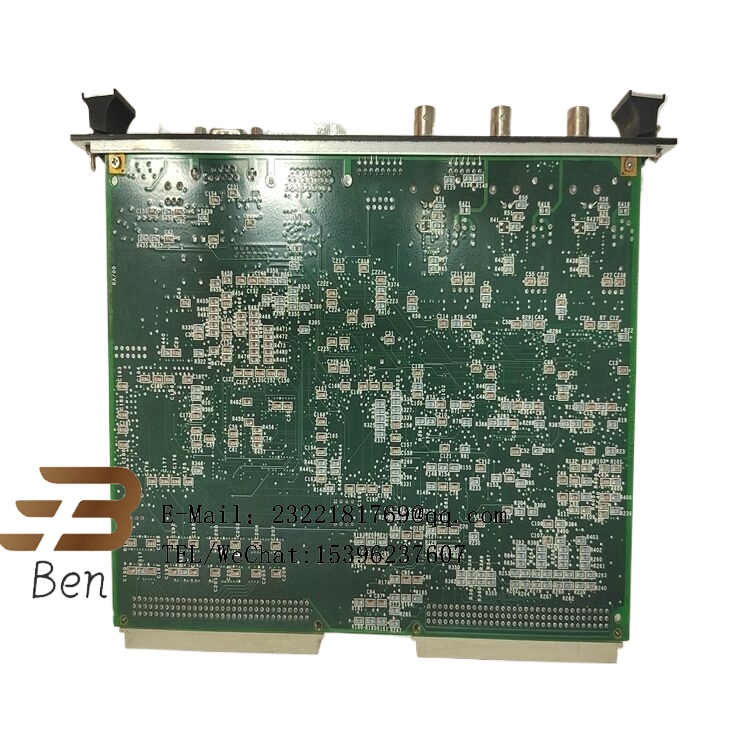

IS200TBAIH1C Industrial automation products

The IS200TBAIH1C is an industrial automation product from General Electric. Specifically, it is an SIS (Safety Instrumentation System) control system solution that utilizes a redundant fault-tolerant control system platform based on TRICON Triple Module Redundancy (TMR) architecture. The control system has three main processors, all I/O signals are triplex design, and through the hardware of two out of three voting processing, to ensure the system’s redundancy and fault tolerance. This makes IS200TBAIH1C widely used in the field of industrial automation, especially in applications requiring high reliability and safety.

The IS200TBAIH1C is an industrial automation product manufactured by General Electric (GE) that features:

Digital port DI5: is designated as the emergency stop function. When running, DI5 must be set to “1”, if it is set to “0”, the alarm signal A102 will appear, and the drive will react according to the function set by parameter 917 (such as the ramp function). After that, the scram input should be reset to “1”, and the alarm ON/OFF input should also be set to “0”, after which the drive can be restarted.

Digital port DI7: is set to start 1 stop (ON/OFF) function. DI7 must be set to logical “1” for connecting the drive to the incoming circuit. If there is no fault, the digital outlet that controls the contactor closing of the armature circuit and the magnetic field circuit is activated. If DI7 is set to “0”, the internal controller will stop working and reset through a delayed digital output.

High node density: Up to 624 sensor actuator nodes can exist in a single work area without significant impact on communication time. This means that more nodes can be added (although this may introduce a small time delay), and there can be an unlimited number of nodes in a factory.

.png)

Reviews

There are no reviews yet.