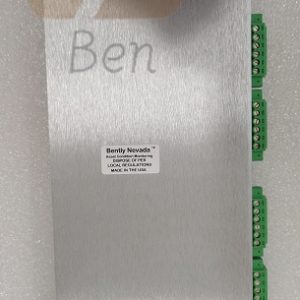

350022M 138607-01 Control pulse card module

It is a powerful and stable control pulse card module, suitable for pulse control and counting applications in industrial automation systems. The 3500/22M Transient Data Interface (TDI) is the interface between the 3500 monitoring system and compatible software (system 1 status monitoring and diagnostic software and 3500 system configuration software). The tdi combines the capabilities of a 3500/20 rack interface module (RIM) with the data acquisition capabilities of a communications processor such as TDXnet.

The TDI is installed in the slot adjacent to the power supply in cabinet 3500. It interfaces with M series monitors (3500/40M,3500/42M, etc.) to continuously collect steady-state and transient dynamic (waveform) data and pass this data to the host software over an Ethernet link. For more information, see the Compatibility section at the end of this document. Static data capture is standard in TDI. However, enabling the disk with an optional channel will allow TDI to capture dynamic and high-resolution transient data. The tdi integrates communication processor capabilities within 3500 racks. Although TDI provides certain functions common to the entire rack, it is not part of the critical monitoring path and has no impact on the proper operation of the overall monitoring system for automatic mechanical protection. Each 3500 rack requires a TDI or RIM, which always takes up a lot 1(next to the power supply)..jpg)

.jpg)

3500-91M 190782-01 The application field of the communication gateway module is mainly concentrated in the field of industrial automation and process control. Specifically, it is often used to monitor and diagnose rotating equipment such as turbines, generators, pumps, etc. This communication gateway module has a comprehensive communication capability, which can collect the monitoring data of the device in real time, such as vibration, temperature, pressure and other parameters, and transmit these data to the monitoring system or data acquisition system for processing and analysis. Through the remote monitoring and management function, the operator can know the running status of the device in real time, and carry out remote diagnosis and control. In addition, the module also has fault diagnosis and early warning function, which can monitor the operating status of the equipment and issue an alarm when an abnormal situation occurs, reminding the operator to deal with it in time. Therefore, it has important application value in the industrial field, and provides equipment protection and operation optimization support for enterprises. .jpg)

.jpg)

.png)

Reviews

There are no reviews yet.