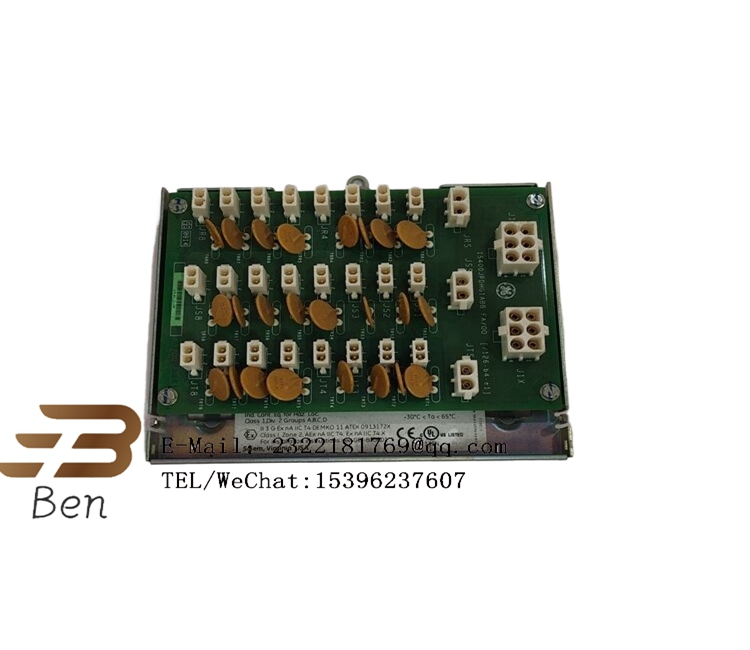

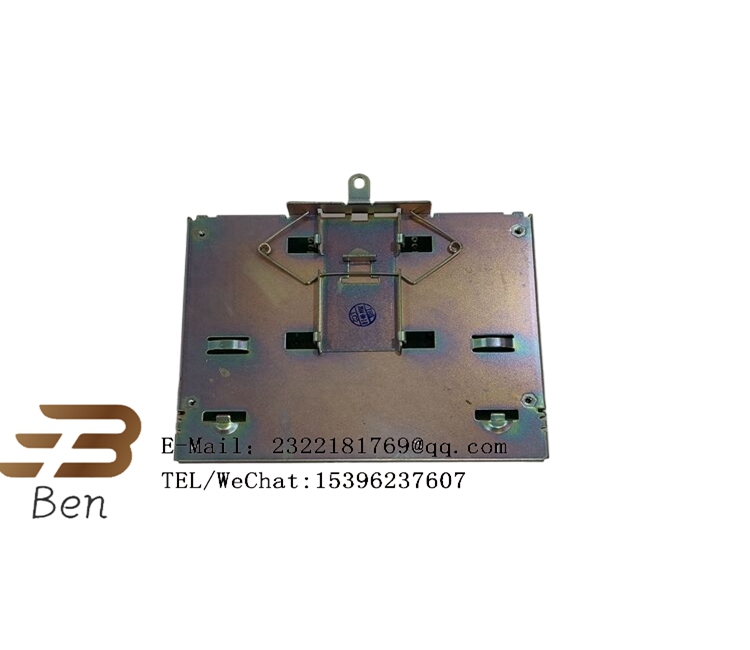

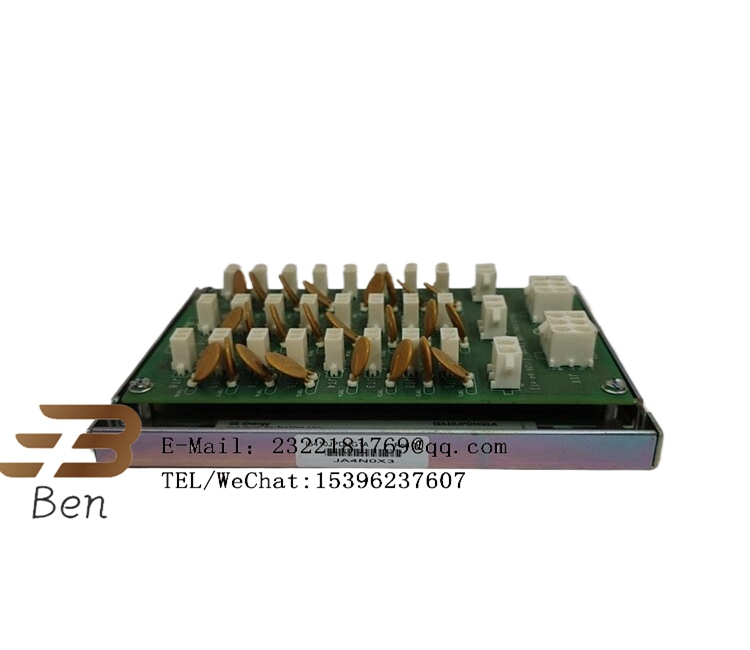

IS400JPDHG1ABB IS410JPDHG1A Shaft velocity feedback sensor

The IS400JPDHG1ABB and IS410JPDHG1A are shaft speed feedback sensors manufactured by General Electric (GE).

These sensors are commonly used in motion control systems in the industrial sector, mounted on mechanical equipment or systems to measure and feedback shaft speed information. Specifically, they can be mounted on the elevator tail pulley to measure shaft speed and output a 4-20mA signal in the RPM range of the shaft.

In addition, both sensors have the following features:

Powerful communication capability: It can be seamlessly connected with other industrial networks, such as PROFIBUS, etc., and easily integrated into the existing industrial environment to achieve real-time data transmission and sharing.

Flexibility and scalability: Users can configure and expand according to actual needs to meet the needs of different scale and complexity of industrial automation.

Input type support: The system supports a variety of input types, such as analog and digital quantities, and can adapt to the signal output of various sensors and actuators.

High performance: It has the characteristics of high precision, high stability and high reliability, which can ensure the precise control of industrial processes, improve production efficiency and reduce the failure rate.

The IS400JPDHG1ABB and IS410JPDHG1A are shaft speed feedback sensors manufactured by General Electric (GE) that are commonly used in motion control systems in the industrial field to measure and feedback shaft speed information in mechanical equipment or systems. Here are some of the main application areas for these axial velocity feedback sensors:

The IS400JPDHG1ABB and IS410JPDHG1A are shaft speed feedback sensors manufactured by General Electric (GE) that are commonly used in motion control systems in the industrial field to measure and feedback shaft speed information in mechanical equipment or systems. Here are some of the main application areas for these axial velocity feedback sensors:

Machine tools and processing equipment: In machine tools and other processing equipment, these sensors are used to monitor the speed of the spindle or table for precise machining control.

Motion control systems: They are used in various motion control systems, such as robots, automated production lines, etc., to monitor the speed of moving parts.

Wind power and power generation equipment: These sensors are used in wind turbines, generators and other equipment to monitor the speed of rotating components and ensure their normal operation.

Conveyor system: In the conveyor system, they monitor the speed of the conveyor belt or drum to achieve accurate conveying and control of materials.

Elevators and lifting equipment: They are installed in elevators, cranes and other equipment to monitor the speed of the lifting mechanism to ensure its safe and stable operation.

Bearings and drivelines: In bearings and drivelines, these sensors monitor the speed of the shaft to ensure the proper operation of the drivelines.

These sensors have the characteristics of high precision, high stability and high reliability, and can feed the shaft speed information to the control system in real time to support real-time motion control and adjustment.

.png)