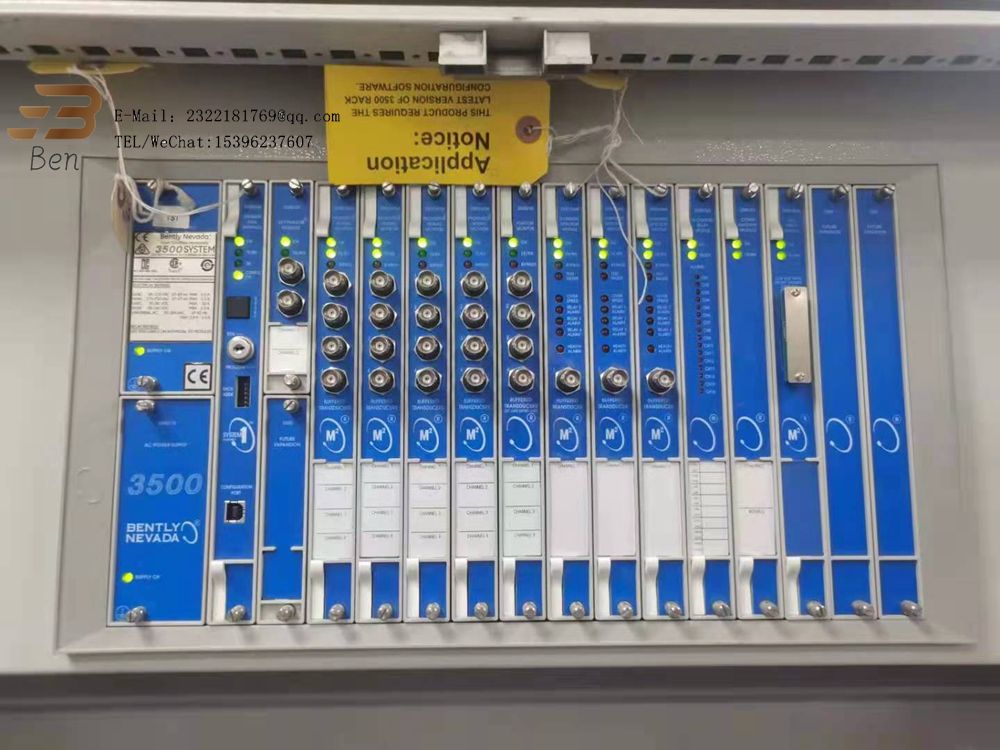

Bently Nevada’s 3500 series online monitoring and protection system. Monitoring and Protection systems provide continuous online condition monitoring and protection for your unit equipment. The Bentley 3500 system works well with Bentley vibration sensor probes and can accept Bentley approach eddy current sensors, velocity acceleration sensors (e.g. 330400,330500) and various composite sensors. It is a world leader in detecting and preventing false trips and false trips of rotating machinery. Installed in more than 80,000 units worldwide, it provides automatic protection values through trip monitoring machines to prevent costly damage when needed. The 3500 system also protects your machines and processes against errant trips that can cause your operations to stop for no reason, resulting in costly downtime or lost production. When connected to System 1* software, it also provides continuous condition monitoring information for proactive maintenance planning. The 3500 system combines the industry’s broadest selection of mechanical measurement parameters with software configurations for virtually all mechanical monitoring scenarios. The 3500 system fully complies with the requirements of the American Petroleum Institute API670 standard for such systems. It is the most powerful and flexible system in the Bentley Nevada legacy frame system, with a variety of features and advanced functions not available in other systems.

Bently 3500/44M Aeroderivitive GT Vibration Monitor

Main features: The self-detection and fault-tolerant design can be configured with multiple redundations, ranging from the addition of a second fully redundant power supply to a full triple modular redundancy (TMR) configuration, which can be used for either selected channels or all channels, enabling the most mission-critical applications to seamlessly connect with the Bentley System1 condition monitoring and diagnostic analysis software platform. The communication gateway module can communicate with plant control and automation systems and is designed to comply with API 670. Design in line with reciprocating compressor application API618 standard; Certified with DNV and Class NK certificates for offshore applications; Certified by the Canadian Standards Association (CSA), Factory Mutual (FM), GOST, ATEX and CE.

Bently Bently 3500 vibration monitoring protection system provides online monitoring function.

The bently3500 system can monitor the vibration of large rotating machinery: steam turbines, water turbines, fans, compressors, turbo expanders, electric motors and generators, exciters, gear boxes, water pumps and more

bently 3500/05 Instrument frame

bently 3500/15 power supply

bently 3500/20 Framework interface module

bently 3500/22M Framework interface module

bently 3500/25 key phase module

bently 3500/01 framework configuration software

bently 3500/40 monitor module channel types: radial vibration, axial displacement, eccentricity, differential expansion

bently 3500/42 Monitor module Channel types: acceleration, speed, absolute shaft vibration

bently 3500/45 Monitor module channel types: axial displacement, differential expansion, bevel-surface differential expansion, shell expansion, valve position

bently 3500/53 Monitor module Channel type: Overspeed tachometer

bently 3500/32 relay module

bently 3500/33 Relay module

bently 3500/92 Communication gateway module

bently 3500/93, 3500/94\3500/95 display device monitor

System Framework 3500/05-01-01-00-00-00

Power Module 3500/15-02-02-00 (3500/15-05-05-00 new)

Interface module 3500/22-01-01-00

Bond phase module 3500/25-01-01-00

Speed measurement module 3500/50-01-00-01

Vibration displacement measurement module 3500/42-09-00

Vibration measurement module 3500/42-01-00

Expansion measurement module 3500/45-01-00

Relay module 3500/33-01-00

Configuration Software 3500/1/1

Configuration cable 130118-0010-02

Bently 3500 series care and maintenance

The maintenance and maintenance of Bently 3500 series mainly includes the following aspects:

- Regular cleaning: Regularly clean the exterior and interior parts of Bentley 3500 Series equipment using dry compressed air or soft cloth to prevent the accumulation of dust, dirt and impurities.

- Power supply and voltage check: Ensure that the power supply voltage of the Bentley 3500 series equipment is stable to avoid damage to the equipment caused by voltage fluctuations.

- Operation monitoring: Regularly check the operating status of Bentley 3500 series equipment, including temperature, vibration, noise and other indicators to ensure the normal operation of equipment.

- Preventive maintenance: Based on the operation of the equipment and the manufacturer’s recommendations, develop and implement a preventive maintenance plan, including regular replacement of worn parts, inspection of cable connections, etc.

- Software updates: Check Bentley 3500 Series devices regularly for software updates to ensure the device has the latest features and performance.

- Troubleshooting: When a Bentley 3500 series device fails, it should be checked and repaired in accordance with the manufacturer’s troubleshooting guidelines to avoid the expansion of the fault.