3300/47-XX-03-01-00 Differential expansion monitor

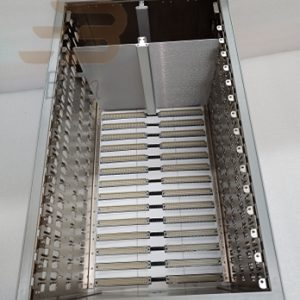

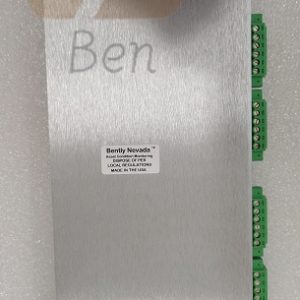

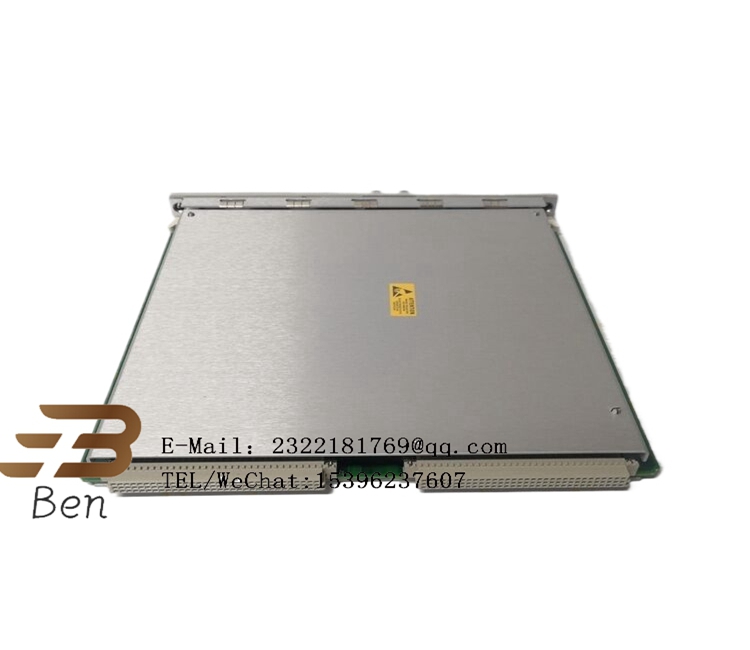

3300/47-XX-03-01-00 is a differential expansion monitor manufactured by Bently Nevada. The product was added to the market in March 2020 and has already been viewed several times. Also known as Bently Nevada, it is part of the 3500 series of mechanical monitoring systems with a wide range of mechanical measurement parameters and software configuration options.

The main function of the device is to detect and prevent missed trips and false positives in rotating machinery, thereby improving the reliability and safety of the system.

Specifically, this differential expansion monitor model is widely used in the field of industrial automation, offering a wide range of mechanical measurement parameters and being configured with software to accommodate almost all monitoring options. In addition, it is highly reliable and ensures the stable operation of the system through self-checking and fault-tolerant design.

In short, the main function of 3300/47-XX-03-01-00 is as a differential expansion monitor for detecting and preventing leakage and false positives in rotating machinery to improve the operational safety and reliability of mechanical equipment.

The application areas of 3300/47-XX-03-01-00 are mainly in automation and industrial process monitoring. This Differential Expansion Monitor is used in a wide variety of complex industrial environments, including but not limited to the following areas:

Oil and gas production: In these industries, this equipment is used to monitor and control critical mechanical parameters to ensure the safety and efficiency of operations.

Chemical manufacturing: In chemical plants, the equipment can be used to monitor key parameters such as temperature and pressure to ensure the stability of the production process and product quality.

Power generation: In power plants, this equipment is used to monitor and control the operating status of power generation equipment to improve the efficiency and safety of power generation.

Pulp and paper production: In these industries, this equipment is used to monitor the operating status of equipment to ensure the continuity of the production process and the quality of the product.

Food and beverage processing: In the food and beverage processing industry, this equipment is used to monitor the operating status of equipment to ensure the quality and safety of products.

Water and wastewater treatment: In these areas, the equipment is used to monitor and control the operating status of water treatment facilities to ensure that water quality meets standards.

In addition, the device is used in distributed control systems (DCS) to automate, monitor and control complex industrial processes. DCS system through a large network of controllers to achieve the centralized management and control of the entire plant or facility.

In summary, 3300/47-XX-03-01-00 has a very wide range of applications, covering a number of important industries from energy to manufacturing to environmental treatment.

BENTLY similar product models:

| 3500-94 147663-01 |

| 3500-94 145988-01 |

| 3500-92 136188-01 |

| 3500-92 136180-01 |

| 3500-70 140471-01 |

| 3500-70 125720-01 |

.png)