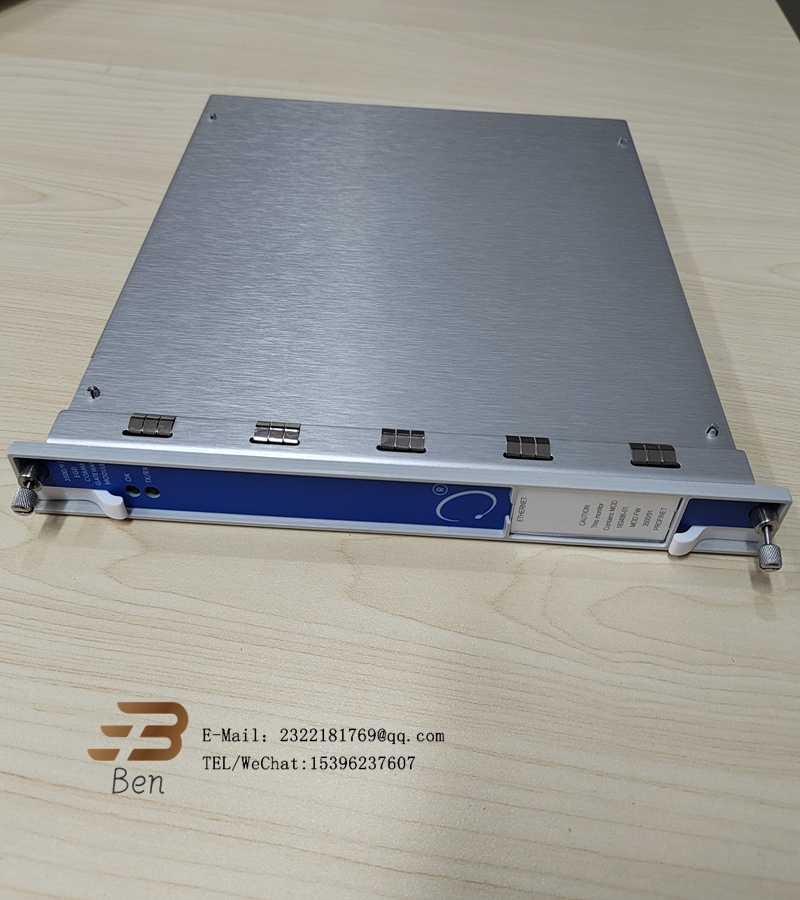

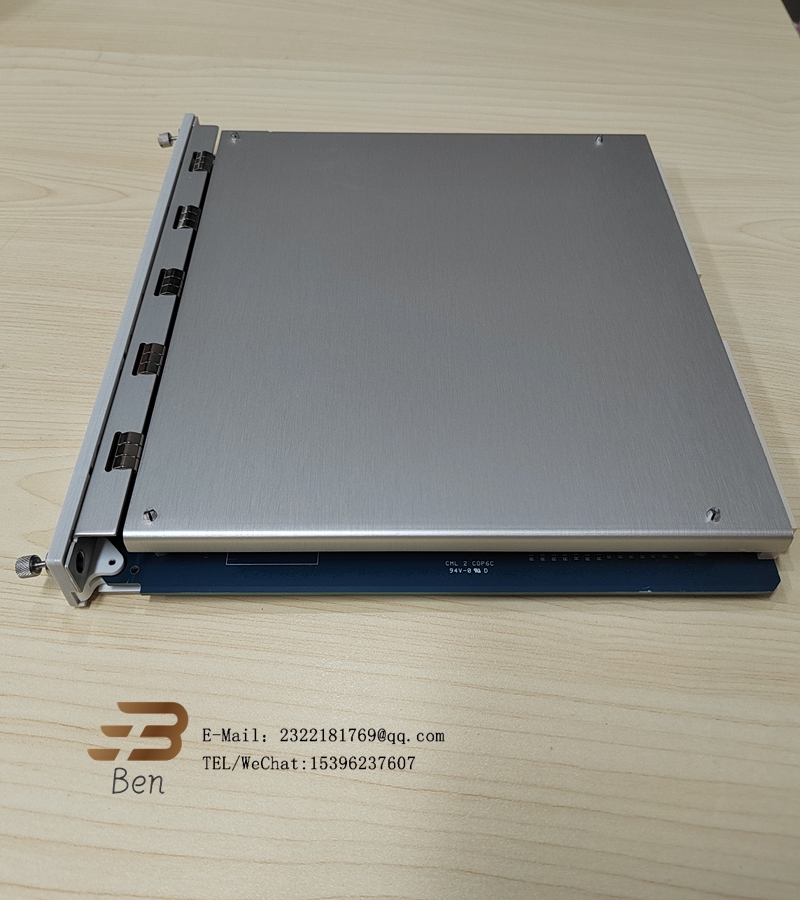

3500-25 149369-01 Dual channel module

The 3500/25 149369-01 is a dual channel module and is also Bently Nevada’s 3500 series power monitor.

As a dual-channel module, it usually refers to an electronic device module with two independent channels, capable of processing two independent signals or data streams at the same time, so as to achieve more efficient data processing capabilities. Specific to the 3500/25 149369-01 model, it may have parallel processing, independence, high precision, multiple interfaces, and programmability.

As Bently Nevada’s 3500 series power monitor, it monitors and records power data such as voltage, current, active power, reactive power, power factor and more in real time, providing power engineers and managers with accurate and reliable power data. The product is mainly used in power quality monitoring, power equipment testing and industrial power monitoring and other fields, such as wind farms, solar power stations, power substations, industrial production lines and other places.

In addition, this model (3500/25 149369-01) is also mentioned as an Ethernet /IP communication module with advanced diagnostic and troubleshooting capabilities.

The BENTLY 3500/25 149369-01 is widely used in various industrial automation fields, including but not limited to power, petroleum, chemical, manufacturing, etc.

The BENTLY 3500/25 149369-01 is widely used in various industrial automation fields, including but not limited to power, petroleum, chemical, manufacturing, etc.

Specifically, it has a significant role in the following areas:

Energy industry: Used in power stations and power plants to monitor and protect generators, turbines, generator sets and other critical rotating equipment, to detect parameters such as vibration, axis displacement, to help predict the operating state of the equipment, and to take protective measures if necessary to prevent equipment damage.

Oil and gas industry: In oil and gas production facilities, this monitoring system can be used to monitor and protect rotating machinery equipment such as pumps, compressors, centrifuges, etc., helping to improve equipment reliability, reduce downtime, and prevent accidents due to mechanical failures.

Chemical industry: In chemical plants, it can be used to monitor and protect key equipment, such as centrifugal pumps, fans, compressors, etc. By monitoring vibration and other parameters in real time, you can detect equipment anomalies and take appropriate maintenance measures.

Manufacturing: In the manufacturing industry, especially involving the manufacture of large rotating machinery, the monitoring system can be used for quality control, performance monitoring and equipment protection.

Transportation: In the field of transportation, such as ships, aircraft and trains, the monitoring system can be used to monitor the status of critical rotating components, improving the safety and reliability of vehicles.

In addition, the BENTLY 3500/25 149369-01, as an industrial automation system, has high-speed data processing capabilities, and can quickly process large amounts of data and complex algorithms, ensuring the real-time and accuracy of industrial automation systems. It can also be used to monitor the vibration and temperature of mechanical equipment so that anomalies can be detected in time for maintenance or repair.

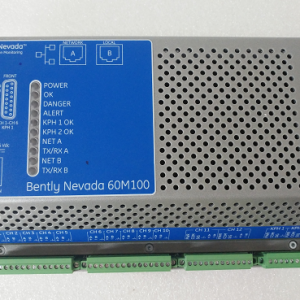

The following are other models of the Emerson brand:

| BENTLY 3500-92 136180-01 |

| 3500-91 |

| 3500-42M 176449-02 |

.png)

Reviews

There are no reviews yet.