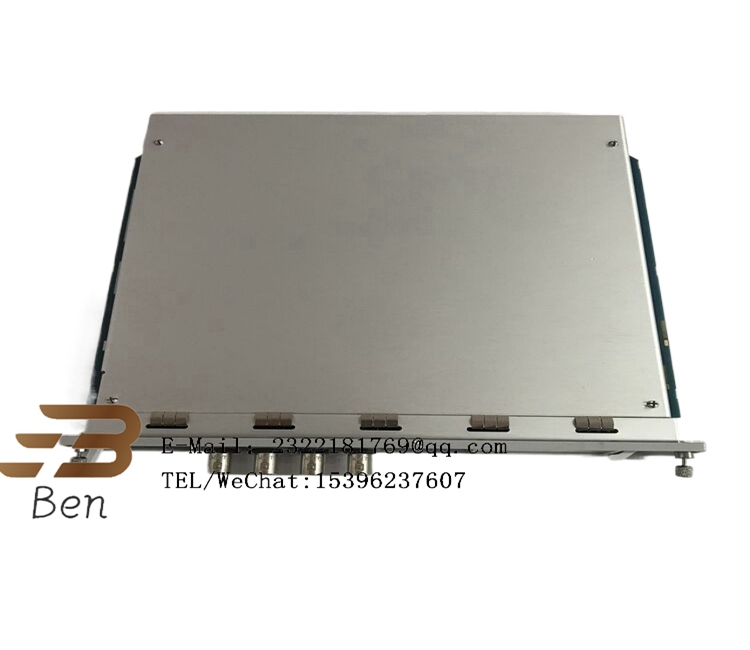

3500-42M 176449-02 Four-channel monitor for mechanical displacement, speed and acceleration

The BENTLY 3500-42M 176449-02 is a four-channel monitor for monitoring mechanical displacement, speed and acceleration. It is mainly used to measure the displacement and vibration of mechanical equipment to provide real-time monitoring and evaluation of the health of equipment. It features high-precision sensors that monitor the displacement and vibration of the device in real time, and provides timely alarm and alarm functions to indicate any potential problems or anomalies. In addition, it has functions such as remote monitoring, data storage and analysis, as well as multiple alarm functions, including high displacement, high speed, high acceleration and bearing wear alarms.

The monitor can be used in a variety of applications, such as vibration monitoring of rotating machinery, bearing monitoring of pumps and compressors, shaft seal monitoring of steam turbines, gear mesh monitoring of gear boxes, etc.

The application areas of 3500-42M 176449-02 are mainly in the field of mechanical condition monitoring and vibration analysis.

Specifically, this device is commonly used to monitor parameters such as vibration, displacement and speed of various rotating machinery and equipment. For example, in the power, petroleum, chemical, metallurgical, mining and other industries, the operating state of rotating machinery such as steam turbines, generators, compressors, pumps and other equipment is crucial to the safety and efficiency of the entire production line. Through the installation of monitoring equipment such as 3500-42M 176449-02, the vibration, displacement and speed data of the equipment can be obtained in real time, and analyzed and processed to determine whether the operating status of the equipment is normal, and whether there are potential safety hazards or failures.

In addition, the equipment is widely used in fault diagnosis and preventive maintenance of mechanical equipment. By analyzing the monitoring data, you can discover the abnormal situation of the equipment in time, and take appropriate measures to repair or replace the equipment, so as to avoid the impact of equipment faults on production. At the same time, through long-term monitoring and analysis, you can also understand the operation rules and wear conditions of the equipment, and provide a scientific basis for preventive maintenance of the equipment.

In short, 3500-42M 176449-02 is a powerful and widely used mechanical equipment condition monitoring equipment, which is of great significance to ensure the safety and efficiency of the production line.

BENTLY similar product models:

| 350022M 138607-01V |

| BENTLY 3500-92 136180-01 |

| 3500-91 |

.png)