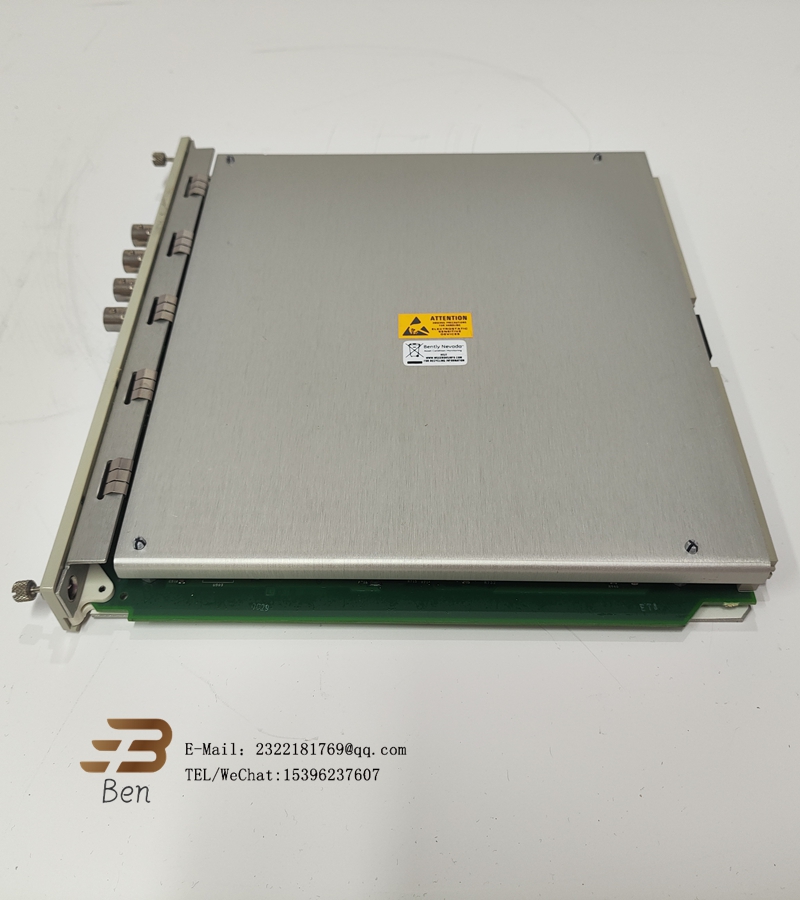

3500-42M 176449-02 High-performance vibration and axial displacement monitoring module

The BENTLY 3500-42M 176449-02 is a high-performance vibration and axial displacement monitoring module designed specifically for rotating machinery to continuously monitor the vibration and axial displacement of mechanical equipment, providing real-time data and fault warning. The module integrates high-precision sensors and signal processing technology to collect parameters such as vibration, temperature, and pressure, and to alert or take protective measures in the event of an abnormal situation. In addition, it has four channels that can accept input from proximity and seismic sensors, adjust the signal to provide a variety of vibration and position measurements, and compare the condition signal with a user-programmable alarm.

3500-42M 176449-02 The main function of the product is used in the field of industrial automation and mechanical equipment monitoring, especially vibration monitoring and shaft displacement monitoring. The module has high-precision analog output and input capabilities, and is able to receive input signals from proximity sensors and seismic sensors, and adjust and process these signals to provide a variety of vibration and position measurements. In addition, it has a multi-channel monitoring function, which can simultaneously monitor multiple different signal inputs. The module is widely used in the health monitoring and fault diagnosis of industrial equipment, helping to prevent and identify mechanical problems in equipment, thereby improving the reliability and operational efficiency of equipment.

.png)