A06B-0590-B372

High-speed serial bus is the connection interface between CNC system and the main computer, which is used for data transmission between the two. In addition to the data transmitted by DNC1 and DNC2, it can also transmit the display data of various CNC screens. Machine tools can therefore be operated with computer monitors and keyboards. Ethernet port is the interface between the CNC system and Ethernet. FANUC offers two types of Ethernet ports: PCMCIA bayonets and embedded Ethernet boards. PCMCIA card can be used to temporarily transfer some data, after use can be pulled out of the card. Ethernet board is installed in the CNC system, so it is used for long-term connection with the host, the implementation of real-time processing unit control.

1 CNC motherboard: used for core control, computing, storage, servo control and so on. The new motherboard integrates PLC functions.

2.PLC board: Used for peripheral action control. The PLC board of the new system has been integrated with the CNC motherboard.

3.I/O boards: Early I/O boards were used for CNC systems and external switching signals. The new type of I/O board mainly integrates the display interface, keyboard interface, handwheel interface, operation panel interface and RS232 interface.

4. MMC board: man-machine interface board. This is a PC computerised card, it does not have to be matched. With CRT, standard keyboard, floppy drive, mouse, memory card and serial, parallel interface.

5.CRT interface board: Used for display interface. In the new system, the CRT interface is integrated into the I/O board.

FANUC NC system function introduction

1. Controlled Path

Number of feed servo axes (feed) controlled by CNC. During processing, each group forms a tool path. Each group can move independently or coordinate at the same time.

2, control axis number (ControlledAxes)

CNC control of feed servo axis total/per track.

3. Simultaneous Controlled Axes (Simultaneously Controlled Axes)

The number of feed servo axes of each trajectory simultaneously interpolated.

4. Axis control by PMC

Feed servo shaft controlled by PMC (Programmable Machine Tool controller). Control instructions are programmed in PMC program (ladder diagram), so it is inconvenient to modify, so this method is usually only used for feed shaft control with fixed movement.

5. Cf Axis Control (T series)

In the lathe system, the rotation position (Angle) of the spindle is controlled by the feed servo motor like other feed shafts. The axis is interlinked with other feed axes to interpolate and process arbitrary curves.

6. Cs contouring control (T series)

In the lathe system, the rotation position (Angle) of the spindle is controlled by the FANUC spindle motor instead of the feed servo motor. The position (Angle) of the spindle is detected by a high resolution encoder mounted on the spindle (not the spindle motor). At this time, the spindle works as a feed servo shaft with a speed of: degrees/min, and can be interpolated together with other feed shafts to produce contour curves.

7. Rotary axis control

Set the feed shaft as the rotary shaft for Angle position control. The Angle of rotation. The available parameter is set to any value. FANUC system usually only the feed axis other than the basic axis can be set as the rotation axis.

8. Controlled Axis Detach

Specify a feed servo shaft out of CNC control without system alarm. It is usually used for turntable control. This function is performed when the machine tool is not using the turntable to unplug the motor of the turntable and remove the turntable.

9. Servo Off

PMC signal was used to turn off the power supply of the feed servo shaft, making it out of CNC control. Hands could move freely, but CNC still monitored the actual position of the shaft in real time. The function can be used to control the movement of the table with the mechanical hand wheel on the CNC machine, or the table, the turntable is mechanically clamped to avoid the overcurrent of the feed motor.

10. Location Tracking (Follow-up)

When the servo shutdown, emergency stop or servo alarm, if the mechanical position of the workbench moves, there will be a position error in the CNC position error register. Position tracking function is to modify the CNC controller monitoring machine position, so that the error in the position error register becomes zero. Of course, whether or not to perform location tracking should depend on the need for actual control.

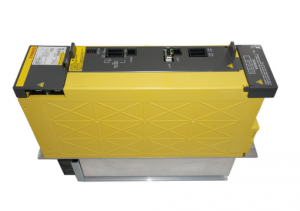

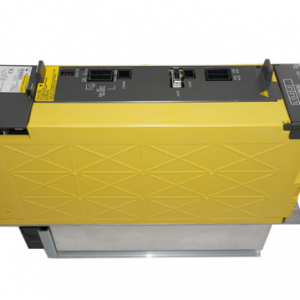

A06B-0116-B203#0100

A06B-6077-H106

A06B-6079-H106

A06B-6079-H208

A06B-6089-H104

A06B-6114-H106

A06B-6120-H075

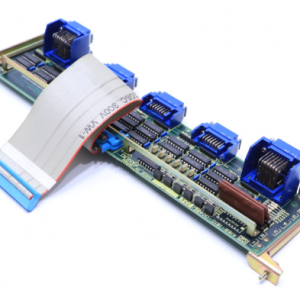

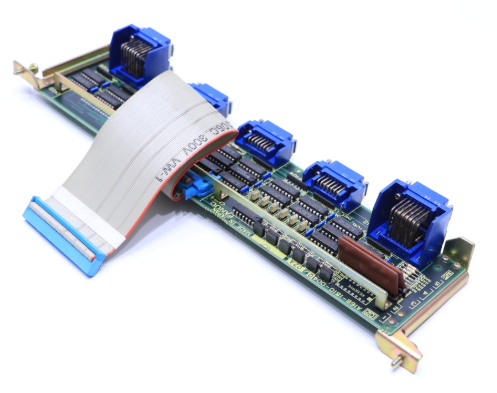

A16B-2203-0073/02A

A20B-2002-0040/07DR

A20B-2002-0310

A20B-2901-0763/02A

A20B-2902-0290/08C

A20B-8200-0927

A230-0604-X003

A860-0302-T001

A860-0326-T103

A90L-0001-0422#50(9WF0624H7D05)

A05B-2452-C900

A81L-0001-0165

A16B-1810-0040

A06B-6114-H209

A06B-6102-H226

A06B-0268-B001

If you need to inquire or purchase ,please send the product models to my email or call me directly .

Contact detail:Mobile/ WeChat/ WhatsApp:+86-15396237607

E-mail:2322181769@qq.com

QQ: 2322181769

Control system (DCS, PLC/SPS, CNC): panel controller, HMI and display panel, industrial PC, drive (frequency converter and servo system), motor, power supply

Allen Bradley :ControlLogix 1756 Series controller, CompactLogix 1769 Series controller, SLC 500 1747 1746 Series controller, PLC-5 1771 1785 Series controller, ProSoft:mvi 69/PS69/mvi 56/mvi 94/mvi 71/mvi 46/3150, ICS TRIPLEX trusted system

ABB:AC800M series controller I/O module, AC800F series controller module, AC31 series controller module, 800xA series module, Bailey INFI 90 module, DSQC robot module spare parts, Advant OCS system spare parts, H&B Freelance module

Bentley Nevada :Bently 3500 monitoring system, Bently 3300 monitoring system, preprocessor, eddy current sensor probe

Schneider :Quantum 140 series :Modicon M340, Modicon Premium :CPU processor module, communication module, etc

Emerson Emerson :Ovation system DCS card, DeltaV system double channel redundant security system, redundant controller

Ge :IS200/DS200 series excitation system card, IC 693/IC 695/IC 697/IC 698/IC 200/IC 660/IC 670 CPU module, communication module, analog and digital module

Invensys Triconex Card :Tricon System card

Invensys Foxboro :I/A series system modules

Honeywell :Alcont, Experion LS, Experion PKS, Experion HS, Plant Scape, TDC 2000, TDC3000, TPS

Yokogawa :CS3000 system CPU

I look forward to hearing from you and to our cooperation every time, my friend