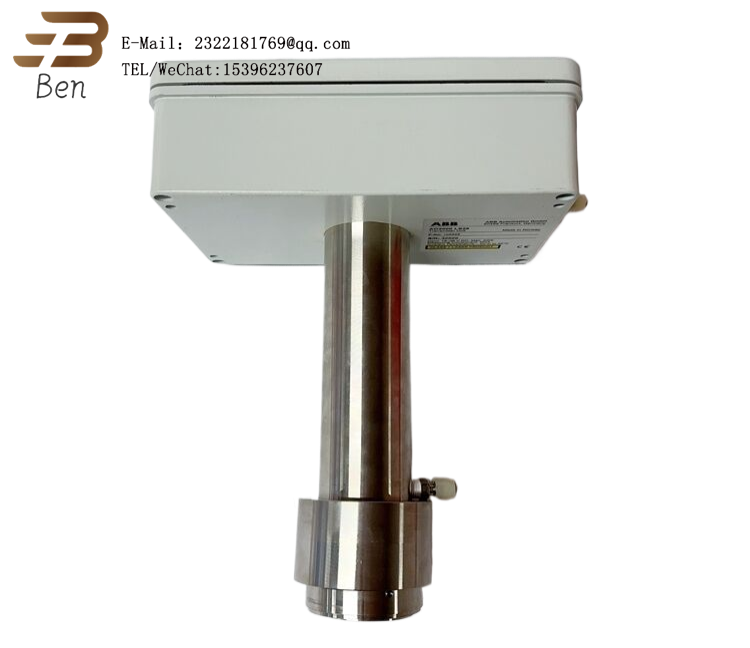

The ABB AO2000 LS25 represents the cutting edge of continuous gas analysis systems within ABB’s Advance Optima platform. Designed for harsh industrial environments, this laser-based spectrometer achieves ±0.5% FS measurement accuracy for O₂, CO, and CO₂ concentrations in combustion control applications. The AO2000 LS25 integrates TÜV-certified NDIR (Non-Dispersive Infrared) technology with in-situ sampling, eliminating traditional sample conditioning systems. Its modular architecture allows seamless integration of up to 6 measurement components, including optional H₂S and CH₄ detection modules.

As part of ABB’s Industry 4.0-ready analytical portfolio, the AO2000 LS25 features predictive diagnostics through ABB Ability™ Analytics, reducing maintenance costs by 40% compared to conventional analyzers. The explosion-proof (ATEX II 2G Ex db IIC T6) enclosure with IP66 protection enables direct installation in Zone 1 hazardous areas. With <2-second response time, this system is critical for optimizing thermal processes in power plants and refineries while maintaining emissions compliance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | AO2000 LS25 |

| Manufacturer | ABB |

| Product Type | In-situ Laser Gas Analyzer |

| Measurement Range | 0-25% O₂, 0-5000ppm CO, 0-20% CO₂ |

| Accuracy | ±0.5% FS |

| Response Time | <2 seconds |

| Optical Path Length | 0.5-20 meters adjustable |

| Operating Pressure | 0.8-1.2 bar abs |

| Ambient Temp Range | -20°C to +55°C |

| Process Temp Limit | 180°C (standard), 350°C (high-temp option) |

| Power Supply | 100-240 VAC, 50/60 Hz |

| Communication | Profibus DP, Modbus TCP/IP, 4-20mA outputs |

| Certifications | ATEX, IECEx, SIL 2, EN 15267-3 |

| Enclosure Rating | IP66/Type 4X |

| Calibration Interval | 12 months |

Key Features and Advantages:

Advanced measurement stability: The AO2000 LS25 employs wavelength-modulation spectroscopy (WMS) to eliminate cross-interference from background gases. Its automatic pressure/temperature compensation maintains <1% drift over 6-month periods.

Smart maintenance capabilities: Built-in test functions validate optical alignment and detector sensitivity. The HotSwap™ module design enables component replacement in <15 minutes without process interruption.

Multi-application flexibility: Configured with ABB’s LS25 laser platform, the system adapts to various duct diameters (200-6000mm) through adjustable beam length. Optional heated optics (H-Option) prevent condensation in high-humidity flue gas streams.

Application Areas:

The ABB AO2000 LS25 excels in:

- Power Generation: Real-time combustion optimization for coal-fired boilers

- Cement Production: Kiln exhaust gas monitoring (NOx/SO₂ compliance)

- Waste Incineration: Dioxin precursor detection in flue gas

- Chemical Processing: Ethylene cracker furnace efficiency control

In steel mills, this analyzer reduces fuel consumption by 3-5% through precise O₂ trim control of reheating furnaces. Municipal waste facilities use its CO measurement for early fire detection in bunker storage areas.

Related Products:

- AO2000 FGA200: Cross-stack FTIR analyzer for multi-component analysis

- AO2020: Upgrade model with integrated H₂O correction

- lenntech CRN64-3-2 A-F-G-E-HQQE Grundfos Pump

- Excitation hybrid input/output device XUD194A丨 XUD194 3BHC018137R0001

- Excitation hybrid input/output device PCD530A102 3BHE041343R0102

- KUC711AE101 3BHB004661R0101 Gate set unit controller

- Communication Module SC560 3BSE008105R1 Submodule Carrier incl local CPU

- Advance Optima series AO2040 process analyzer module

Installation and Maintenance:

Installation preparation: Verify process pipe diameter matches optical path requirements before mounting the AO2000 LS25. Ensure purge air supply (0.5-6 bar, ISO 8573-1 Class 3) is available for lens protection. Allow 500mm clearance around the analyzer for servicing access.

Maintenance recommendations: Perform quarterly window cleanliness checks using the built-in transmission monitor. Replace desiccant cartridges (P/N DSC-25) annually in high-humidity environments. Use ABB’s CalWin software for automated zero/span calibration every 6 months.