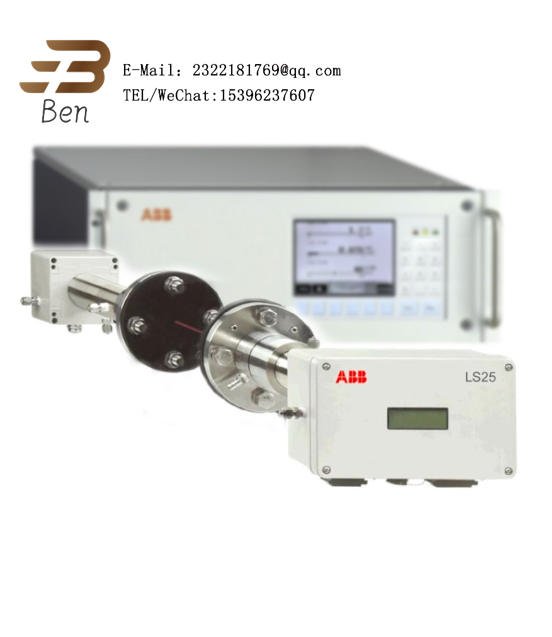

The ABB EL3020 is a next-generation continuous emissions monitoring system (CEMS) within ABB’s EasyLine series, designed for precise O₂ and combustibles measurement in industrial processes. This laser-based analyzer combines tunable diode laser absorption spectroscopy (TDLAS) with advanced signal processing, achieving ±0.2% O₂ accuracy at 650°C flue gas temperatures. The EL3020’s modular design allows simultaneous measurement of up to 4 gas components, including optional CO and NOx detection modules.

As part of ABB’s digitalization-ready platform, the EL3020 features built-in predictive diagnostics through ABB Ability™ Smart Sensor technology. Its rugged IP66/NEMA 4X enclosure withstands vibration levels up to 2g (15-2000Hz), making it ideal for direct installation on rotating equipment. The analyzer’s <1-second response time enables real-time combustion control in power plants and chemical processing facilities, helping users achieve up to 98% fuel efficiency while maintaining EPA 40 CFR Part 60 compliance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | EL3020 |

| Manufacturer | ABB |

| Product Type | In-situ Laser Gas Analyzer |

| Measurement Range | 0-25% O₂, 0-5000ppm CO |

| Accuracy | ±0.2% O₂, ±1% FS CO |

| Response Time | <1 second |

| Measurement Path | 0.3-20 meters adjustable |

| Process Temperature | -40°C to +650°C (standard) |

| Ambient Temperature | -20°C to +55°C |

| Power Supply | 85-264 VAC, 47-63 Hz |

| Output Signals | 4-20mA, Modbus RTU, Profibus DP |

| Protection Class | IP66/NEMA 4X |

| Certifications | SIL 2, ATEX II 2G Ex db IIC T6 |

| Calibration Interval | 24 months |

Key Features and Advantages:

Advanced measurement reliability: The EL3020 employs wavelength-stabilized laser technology that eliminates interference from dust and steam. Its automatic pressure compensation maintains <0.5% measurement drift over 12-month operation cycles.

Smart maintenance capabilities: Integrated self-check functions monitor laser intensity and detector sensitivity. The HotSwap™ optical module enables component replacement in <10 minutes without process shutdown.

Multi-application flexibility: The analyzer’s adaptive beam path configuration accommodates duct diameters from 0.5m to 8m. Optional heated sample probes (HSP-EL30) prevent condensation in wet gas streams. The WebServer interface allows remote configuration via standard browsers.

Application Areas:

The ABB EL3020 excels in:

- Waste-to-Energy Plants: Continuous monitoring of boiler combustion efficiency

- Cement Production: Kiln emission control for NOx/SO₂ compliance

- Oil Refineries: Flare gas monitoring and safety shutdown systems

- Pulp & Paper Mills: Recovery boiler optimization

In steel manufacturing, this analyzer reduces natural gas consumption by 4-7% through precise O₂ trim control of reheating furnaces. Chemical plants utilize its fast CO detection for early warning of partial combustion in reformers.

Related Products:

- EL3010: Basic version with single-component measurement

- EL3030: Multi-gas analyzer with CH₄ detection

- Advance Optima series AO2040 process analyzer module

- ABB AO2000 LS25 Advance Optima continuous gas analysis system

- Supply modules 500PSM02 and 500PSM03

- Industrial automation module PFSK152 3BSE018877R1

- PCD232 PCD232A 3BHE022293R0101 PEC80-CIO Industrial process control

Installation and Maintenance:

Installation preparation: Verify process pipe diameter matches laser path requirements before mounting the EL3020. Ensure purge air supply (1-6 bar, ISO 8573-1 Class 2) is available for optical window protection. Maintain 600mm service clearance around the analyzer.

Maintenance recommendations: Perform quarterly optical window inspection using the built-in transmission monitor. Replace desiccant cartridges (P/N DSC-EL30) annually in high-moisture environments. Use ABB’s CalWin Pro software for automated span gas validation every 6 months.