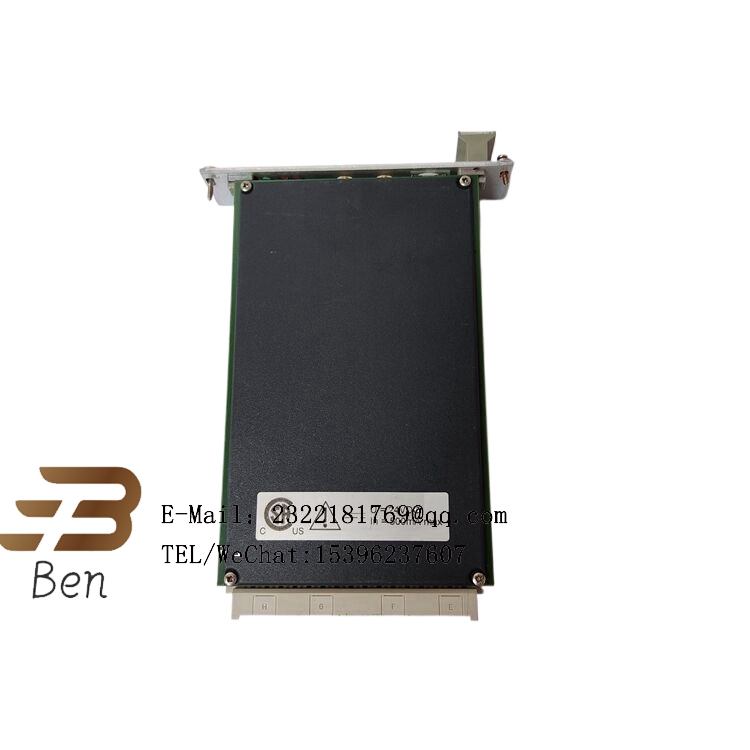

EMERSON A6410 Mechanical condition monitor

The EMERSON A6410 is a mechanical condition monitor designed to monitor valve position and housing expansion in rotating equipment such as pumps, compressors, steam turbines, etc. It is part of the AMS 6500 Mechanical Health Management system from Emerson Process Management and is used to provide critical information about equipment status to help prevent potential mechanical failures.

The EMERSON A6410 is a two-channel valve and housing expansion monitor designed to provide high reliability for the plant’s most critical rotating machinery. This 1-slot monitor is used in conjunction with other AMS 6500 monitors to form a complete API 670 mechanical protection monitor.

Features include accurate monitoring of valve position and housing expansion, and reliable protection of machinery by comparing parameters to alarm set points, driving alarms and relays. Housing expansion monitoring typically consists of two inductive displacement sensors (or LVDTS) mounted axially, parallel to the shaft, on both sides of the turbine housing.

The A6410 also has powerful automatic control technology, with the eddy current sensor of the measuring coil connected to the oscillator circuit, which generates a high frequency signal through the transmitter to detect the distance between the sensor head and the target material.

.png)