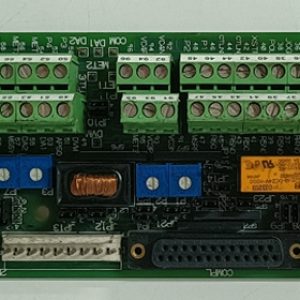

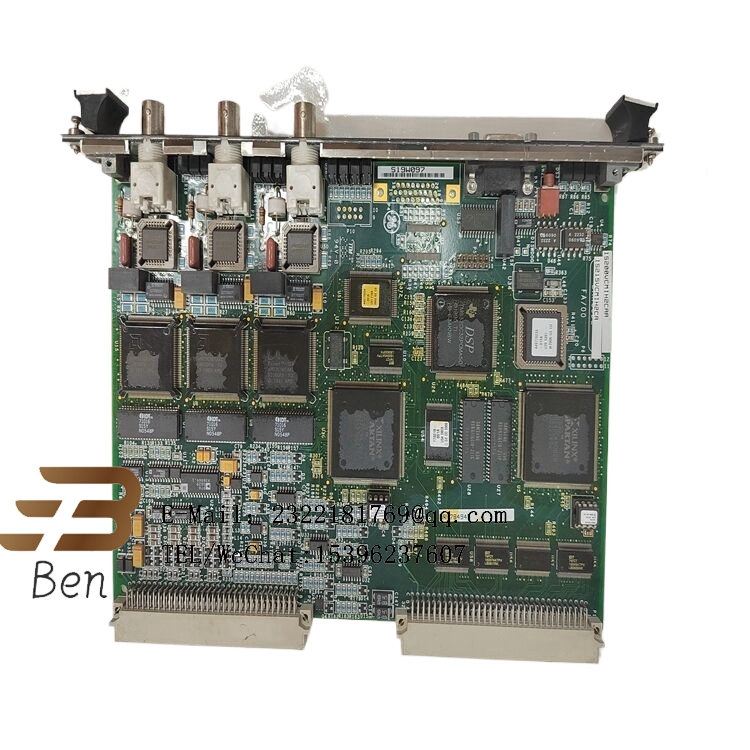

IS200ESELH1A Input/output module

IS200ESELH1A is an input/output module from GE (General Electric). This product is mainly used in industrial automation and control systems to achieve electrical signal input and output functions.

Specific features of the IS200ESELH1A may include electrical control and automation, data acquisition and transmission, fault diagnosis and alarm, and remote monitoring and maintenance. It can control the operation and stop of related electrical equipment and adjust its working state by receiving control instructions from the upper computer or the operator. At the same time, it can also collect the electrical parameters, operating status and other information of the industrial site in real time, and transmit these data to the host computer or control system for processing and analysis through the communication interface.

Electrical control and automation: IS200ESELH1A may be used as part of an industrial automation control system to enable remote control, automated operation and monitoring of electrical equipment. It can control the operation and stop of related electrical equipment and adjust its working state by receiving control instructions from the upper computer or the operator.

Data acquisition and transmission: the device may have the data acquisition function, which can collect the electrical parameters, operating status and other information of the industrial site in real time, and transmit these data to the host computer or control system for processing and analysis through the communication interface.

Fault diagnosis and alarm: The IS200ESELH1A may have a fault diagnosis function that can detect and diagnose faults or abnormal conditions of electrical equipment and notify the operator or control system in a timely manner through an alarm mechanism. This helps to find and solve problems in time to ensure the normal operation of industrial production.

Remote monitoring and maintenance: The IS200ESELH1A may support remote monitoring and maintenance through communication interfaces and network connections. Operators or engineers can access and control the equipment through remote terminals, view its running status and parameters in real time, and perform remote debugging and maintenance operations.

.png)