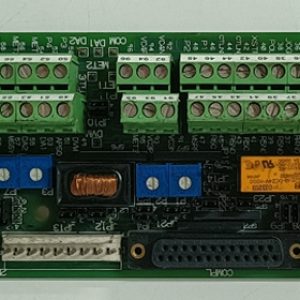

IS200TSVOH1B Industrial control equipment

The IS200TSVOH1B is a rack-mounted power board or related industrial control device from General Electric (GE). This device is commonly used in industrial automation and control systems, especially in conjunction with more advanced Speedtronic systems such as GE’s Mark VI to manage industrial gas and steam turbine systems.

IS200TSVOH1B has a high-performance CPU, based on the latest technology, with high-speed computing and high-speed data throughput capabilities. It supports a variety of IEC languages and C languages, making user programming more flexible. In addition, it has a wide range of I/O processing capabilities, can handle up to 32K I/O, suitable for a variety of complex application scenarios.

The IS200TSVOH1B also has a variety of safety features, such as an extensive diagnostic mechanism, live plug and pull capability, built-in intelligent switching fuse, etc., to ensure system reliability and safety. It can also support automatic voltage adaptation, eliminating the need for jumper selection of different input voltages, simplifying the configuration process.

Overall, IS200TSVOH1B is a powerful, flexible and reliable industrial control equipment, widely used in a variety of industrial automation and control systems.

High-speed computing and data processing: The device uses a CPU based on the latest technology, with high-speed computing and high-speed data throughput capabilities, which can easily handle a variety of complex applications.

Programming flexibility: Supports a variety of IEC languages and C languages, providing users with flexible programming options, so that users can program according to specific needs, to achieve different control logic.

Extensive I/O processing capability: The controller can handle up to 32K I/O in a variety of standard programming languages, which means that it can interact with a large number of external devices and sensors to achieve data acquisition and control.

Reduced downtime: The device has a wide range of diagnostic mechanisms and live plug and unplug capabilities, which help reduce downtime and increase productivity.

Supports a variety of applications: The backplane (rack) has 12 slots and 16 slots. The backplane (rack) supports power-on insertion and removal. Users can select and configure the backplane according to application requirements. In addition, it can interface with a variety of external devices and drivers, such as the Speedtronic series of steam and gas turbine management systems.

Automatic voltage adaptation function: Each power module has automatic voltage adaptation function, the user does not need to choose a different input voltage jumper, which simplifies the configuration process and improves the adaptability of the device.

Fault detection and indication: The IS200TSVOH1B also provides MOV fuse loss detection function, and visually displays SCR gate pulse, power and isolation power status and MOV fuse loss information through the LED indicator, which helps users find and solve problems in time.

.png)