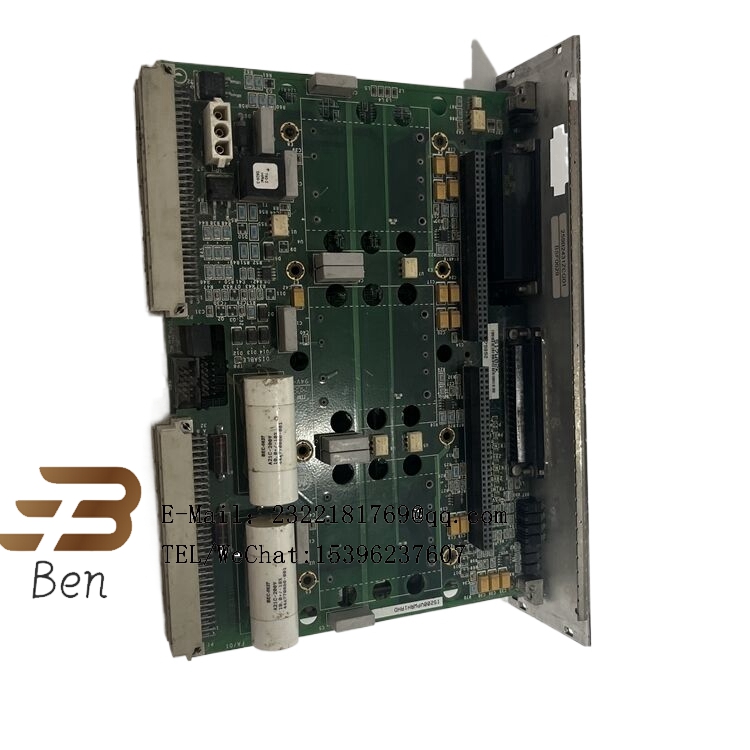

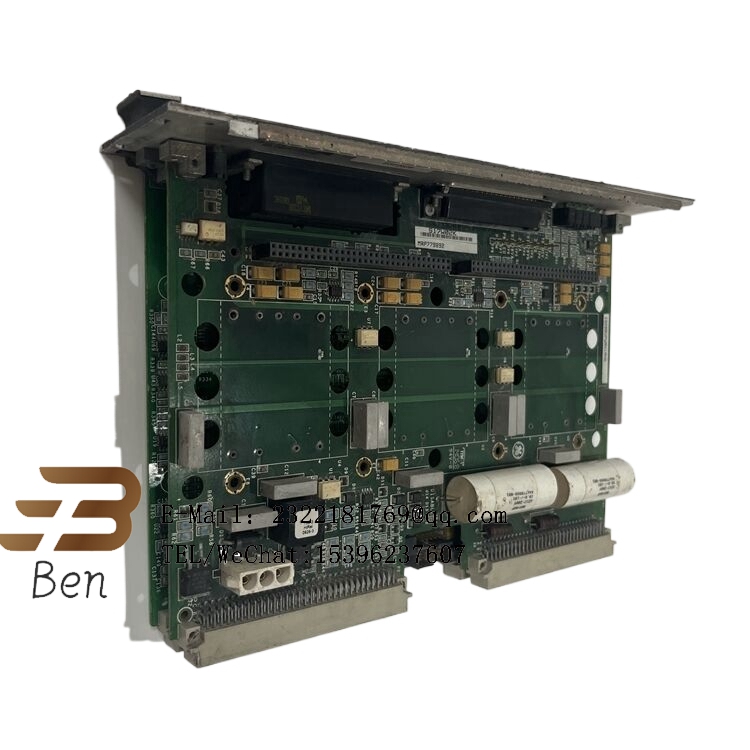

IS200TVBAH2A Programmable logic controller

The IS200TVBAH2A uses a high-performance processor and advanced control algorithms to ensure stable operation in a variety of complex and demanding industrial environments. In addition, it may also have a variety of protection mechanisms, such as overcurrent, overvoltage, overheating and other protection to improve the reliability and safety of the system.

In order to meet the needs of different industrial field signals, IS200TVBAH2A may provide a variety of types of I/O interfaces, such as analog input/output, digital input/output, communication interfaces, etc. These interfaces can connect various sensors, actuators, human-machine interfaces and other devices to achieve data acquisition, processing and transmission.

IS200TVBAH2A supports a variety of programming languages, such as ladder diagram, function block diagram, instruction table, etc., to meet the programming needs of different users. At the same time, it also provides a variety of configuration options, such as channel configuration, parameter setting, fault diagnosis, etc., convenient for users to flexibly configure and debug according to actual requirements.

IS200TVBAH2A adopts a modular design to integrate various functions in one module, which improves the integration and reliability of the system. At the same time, the modular design also facilitates the installation, maintenance and upgrade of users.

IS200TVBAH2A is used in a variety of industrial automation and control systems, such as manufacturing, power, chemical, oil and gas, water treatment, environmental monitoring and other fields. It can be used to control various equipment and processes, and realize the functions of data collection, processing, transmission and monitoring.

.png)