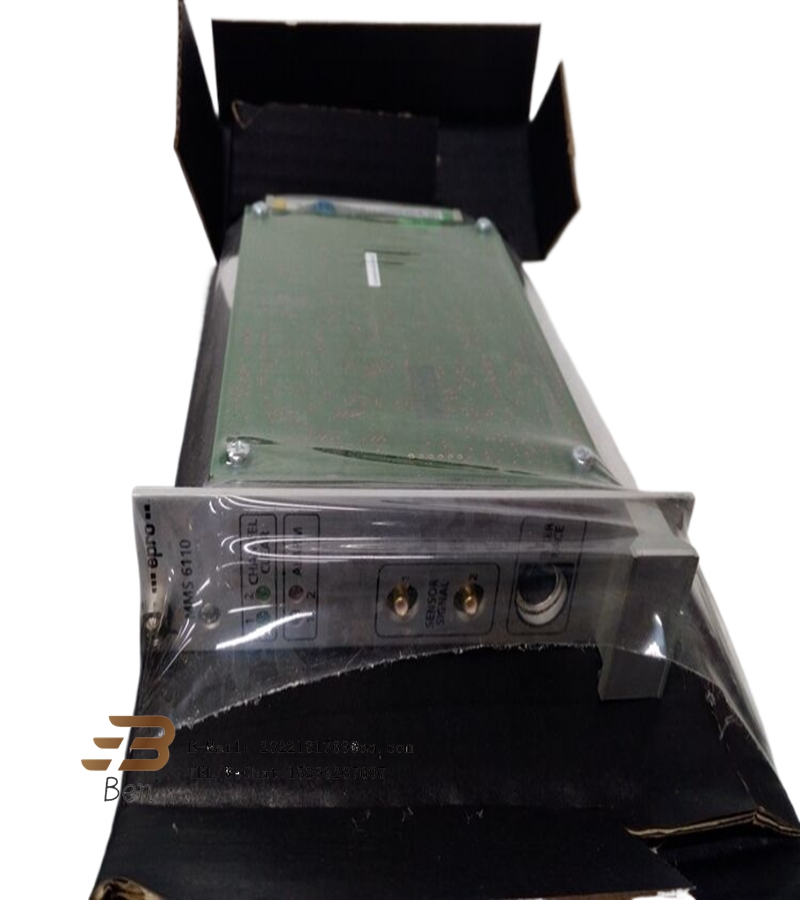

MMS6110 dual channel shaft vibration measurement module

The MMS6110 is a two-channel shaft vibration measurement module. The module is mainly used to monitor and protect various types of turbine-machinery such as steam turbines, gas turbines, compressors, fans, gearboxes, blowers and centrifuges.

Specifically, the MMS6110 module has the following features and functions:

Signal input: The module has two independent eddy current sensor signal inputs, namely SENS 1H (z8) /SENS 1L (z10) and SENS 2H (d8) /SENS 2L (d10). These sensors can be made using the PR642X series eddy current sensor and its accompanying preprocessor produced by epro, Germany, or sensors of the same type produced by other manufacturers.

Working principle: The MMS6110 uses advanced measurement technology to accurately measure the relative vibration of the axial diameter, and improves the efficiency and operation safety through the characteristics of high precision, high stability and fast response.

Application scope: The module is suitable for various industrial environments and application scenarios, and can detect equipment faults and anomalies in time to ensure the normal operation of mechanical equipment.

Redundant design: The MMS6110 features redundant power inputs that allow sensors or modules to be replaced on the run, enhancing system reliability and flexibility.

Extended functions: In addition to the basic vibration measurement functions, the MMS6110 also features a variety of output interfaces and extended self-test functions, including built-in sensor self-test to ensure monitoring accuracy and reliability.

In summary, the MMS6110 is a high-performance, multi-functional dual-channel shaft vibration measurement module that is widely used in industrial automation and vibration measurement to monitor and protect various types of turbine-machinery.

The application areas of MMS6110 are very wide, covering a number of modern industrial fields. The following main application areas can be summarized:

The application areas of MMS6110 are very wide, covering a number of modern industrial fields. The following main application areas can be summarized:

Power industry: MMS6110 is widely used in the power industry to monitor and protect shaft vibration of large rotating equipment such as steam turbines and gas turbines.

Oil and Gas industry: This module is used in the oil and gas industry to monitor the speed and vibration status of equipment such as pumps and compressors to ensure the safe operation of equipment.

Chemical industry: In the chemical industry, the MMS6110 is used to monitor the shaft vibration of various rotating equipment such as reactors, centrifuges, etc., to improve the safety and efficiency of the operation of the equipment.

Metallurgical industry: In the iron and steel metallurgy industry, MMS6110 is used to monitor the shaft vibration of blast furnaces, converter and other equipment to ensure the stability and safety of the production process.

Transportation industry: In the transportation sector, the MMS6110 is used to monitor critical components such as engines and transmission systems on vehicles such as trains and ships to ensure their normal operation.

Environmental Monitoring and control: In addition, the MMS6110 is also used in environmental monitoring and control systems for real-time monitoring and analysis of environmental parameters such as temperature, pressure, flow, etc.

Building automation: In the field of building automation, the MMS6110 is used to monitor various equipment and systems in the building, such as elevators, air conditioning systems, etc., to improve the level of intelligence and operation efficiency of the building.

Water conservancy and other industrial fields: MMS6110 is also widely used in other industrial fields, such as water supply, sewage treatment, textile, paper making, chemical industry, etc., for monitoring and controlling the operating status of various machinery and equipment.

In summary, the MMS6110 plays an important role in several industrial sectors due to its high reliability and non-contact measurement characteristics, ensuring the safe and stable operation of equipment and improving overall production efficiency.

.png)

Reviews

There are no reviews yet.