Roll Supply Unit

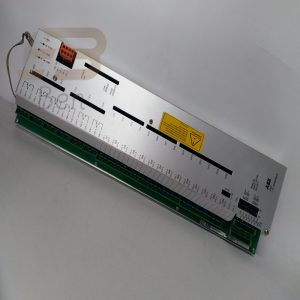

PFSA140 3BSE006503R1 Roll Supply Unit

PFSA140 3BSE006503R1 Roll Supply Unit

Product net weight: 23.3 kg

Roll supply device is one of the important equipment in steel rolling production line, which is mainly used to provide the required rolls to the rolling mill to ensure the continuity and efficiency of the rolling process. The device usually includes roll storage, conveying, positioning and replacement subsystems to ensure that the roll can accurately and quickly reach the working position of the mill.

The following are the main components of the roll supply unit and their functions:

- Roll storage system: This system is responsible for storing different sizes and types of rolls to meet the needs of rolling different products. Storage systems are usually designed with multi-layer shelves or three-dimensional warehouses to maximize storage space and facilitate management.

- Roll transfer system: This system is responsible for transporting the rolls from the storage location to the working location of the mill. The conveying system can be designed and selected according to the specific needs of the production line by mechanical, hydraulic or pneumatic means.

- Roll positioning system: This system ensures that the roll can be accurately positioned at the working position of the mill for rolling operation. The positioning system usually includes sensors, controllers and actuators to achieve precise control of the roll position.

- Roll change system: During the rolling process, when the roll wears to a certain extent, a new roll needs to be replaced. The roll change system is responsible for removing the old roll automatically or manually and installing the new roll onto the mill.

Xiamen Xiongba Electronic Commerce Co. LTD

FROM:Mr. Wei

E-Mail:2322181769@qq.com

TEL/WeChat:15396237607

In addition, the roll supply unit may be equipped with the following auxiliary functions:

- Roll preheating system: In some rolling processes, it is necessary to preheat the roll to improve the rolling effect and extend the roll life. The preheating system usually adopts induction heating or resistance heating.

- Roll cleaning system: used to clean the roll surface before replacing the roll to remove oil, rust and other impurities to ensure rolling quality.

- Roll inspection system: used to detect the wear of the roll, surface quality and other parameters, in order to timely replace the roll or maintenance.

We do other brands: ABB, Allen-Bradley, Schneider, GE (General electric), Westinghouse, FANUC, Bently, KUKA, Foxboro, Triconex, Honwell, YASKAWA, etc., if you need, you can contact me, look forward to your consultation.