Servo drive module UAD149A0001 3BHE014135R0001

UAD149A0001 3BHE014135R0001 is a servo drive module.

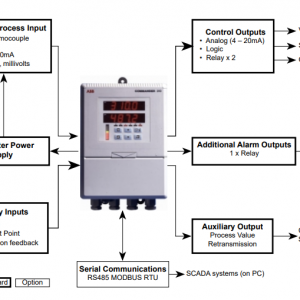

This servo drive module has the following main features:

High-performance servo control: It can precisely control the speed, position and torque of the motor to achieve precise control of the mechanical system.

Intelligent protection function: Monitor the working status of the motor and the driver, once abnormal conditions are detected, protective measures will be taken in time to prevent equipment damage.

Communication interface: Support data exchange and remote monitoring with other devices or control systems to achieve real-time monitoring and remote control of the driver module.

Flexible configuration: Users can set and adjust parameters according to specific application requirements to achieve the best control effect.

High reliability and stability: After rigorous testing and verification, it can operate stably in harsh working environments for a long time.

UAD149A0001 3BHE014135R0001 servo drive module has a wide range of applications in many fields, such as CNC machine tools, industrial robots, printing equipment, packaging machinery, material handling, textile equipment and medical equipment.

UAD149A0001 3BHE014135R0001 servo drive module has a wide range of applications, mainly including the following aspects:

UAD149A0001 3BHE014135R0001 servo drive module has a wide range of applications, mainly including the following aspects:

Industrial automation: In the automated production line, it is used to control various automated mechanical equipment and production lines to achieve high-precision and high-speed production tasks.

CNC machine tools: Control servo motors in CNC machine tools to perform precise cutting, milling and drilling operations to improve machining accuracy and efficiency.

Robotics:

Industrial robots: Used to drive the various joints of industrial robots, provide accurate motion control, and realize automatic operations such as welding, handling, and assembly.

Collaborative robots: Provide fine motion control in robots that collaborate with humans, ensuring safe and efficient cooperation.

Packaging and printing equipment:

Packaging machinery: Control the moving parts of packaging equipment to achieve high-speed, accurate packaging operations.

Printing machinery: Used for servo control in printing presses to achieve high-quality printing results and accurate alignment control.

Textile machinery: Used to control the servo motor in textile machinery, to achieve high-precision textile, weaving and dyeing operations, improve product quality and production efficiency.

Medical equipment:

Imaging equipment: Control the moving parts in medical imaging equipment such as CT and MRI to achieve high-precision scanning and imaging.

Surgical robots: Provide precise motion control in surgical robots to assist doctors in complex surgical operations.

Printed circuit board (PCB) manufacturing: Control the moving parts in PCB manufacturing equipment to achieve high-precision drilling, cutting and assembly operations to improve production efficiency and product quality.

Semiconductor manufacturing: Used for precision motion control in semiconductor manufacturing equipment to ensure high precision and reliability in the manufacturing process.

.png)